Smets Technology GmbH

Pioneering Excellence in Rubber Removal, Demarking, Retexturing, Surface Cleaning, and Friction Testing

Smets Technology GmbH stands at the forefront of ultra-high-pressure water technology, focusing on rubber removal, demarking, retexturing, and surface cleaning.

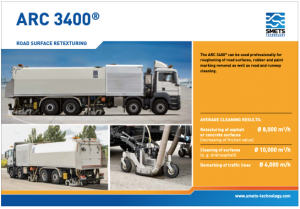

Known for our innovative ARC-Series, we have set a new benchmark in rubber removal efficiency, delivering unparalleled performance in maintaining runway safety and integrity.

On roads, our expertise in demarking and retexturing is unmatched. We provide advanced solutions for the removal of outdated markings and the revitalization of surface textures. This precision ensures the preservation of asphalt and concrete surfaces, enhancing their longevity and maintaining optimal friction levels for safety. Our system is also renowned for its capability to rejuvenate thermoplastic markings through the increase of the reflectivity.

Surface cleaning and friction testing are other key areas where Smets Technology excels. Our comprehensive solutions guarantee impeccably clean, safe, and compliant runway and road surfaces, including coloured asphalt and concrete. Our friction testing equipment, acknowledged by ICAO, offers precise and reliable measurements critical for adhering to safety standards.

Smets Technology is deeply committed to environmental sustainability. Our operations are centered around the efficient and responsible use of water, significantly reducing the environmental impact. The design of our equipment focuses on resource efficiency, notably in reducing water consumption and ensuring lower after-sales costs.

Our customer-focused approach ensures that every product and service is specifically tailored to meet the distinct needs of each project. We collaborate closely with our clients, offering solutions that not only meet but exceed their expectations in rubber removal, demarking, retexturing, surface cleaning, and friction testing.

Benefit from over 45 years of practical experience:

- No Chemicals, only water: Maximum cleaning performance with the lowest water consumption world-wide (only 1.4 liters per treated sqm)

- Unique control: Fully controlled by a single touchscreen in the driver’s cabin

- Longest warranty of all systems world-wide on the superstructure

- Global design: All trucks are permitted to drive on public roads without the need to mount or dismantle anything

- Fastest evacuation: Under 10 seconds with the push of a button

- Lowest after-sales costs through unique nozzles, patented swivel and unique rotation system

The ARC-Series:

- High Performing Rubber Removal Trucks

- Compact Design

- Lowest Water Consumption Per Treated M2

- Demarking Cleaning Head And Front Crane As Additional Options

The MRT-Series:

- Demarking Trucks With A Front Crane For The Removal Of Thermoplastics, Coldplastics And Paint Markings

- Compact Design

- Controllable By A Single Touchscreen In The Driver’s Cabin

- Lowest Maintenance Costs From All Units World-Wide Due To Unique Nozzle Technology

Discover more about our cutting-edge solutions in rubber removal, demarking, retexturing, surface cleaning, and friction testing at Smets Technology GmbH

Downloads

Products

ARC 1000

ARC 1600

ARC 2400

Videos

Images

Company News

Federal Aviation Administration (FAA) guidelines on the frequency of friction surveys

Shaping the Future of Runway Maintenance: Friction Testing and Rubber Removal

Contact

Handwerkerstraße 5A

15366 Hoppegarten

Germany

- +49 [0]3342 – 508 95