Case Study - London Southend Airport – Standard 3 EDS Upgrade and System Expansion

| Company | Robson Handling Technology |

|---|---|

| Date | 03.08.2022 |

Project:

London Southend Airport – Standard 3 EDS Upgrade and System Expansion (Click here to Download as a PDF)

1 Introduction

Robson Handling Technology were recently awarded a contract by Southend Airport for the baggage system expansion and upgrade to standard 3 EDS machines.

The new system consists of a new out of gauge (OOG) line and new in-gauge line (utilising existing check-in and collector delivery lines) both incorporating Std. 3 EDS machines. A link line is provided from the OOG system to the In-gauge system which can be used to bypass the in-gauge x-ray during failure or maintenance. This reduces the impact on operational staff during down times on the in-gauge system and provides the airport with greater resilience.

A key feature of the design was the ability to install the project in a detailed phased manner which allowed Robson to install the new equipment, including one of the new Std. 3 EDS machines, without taking the current system out of operation at any time.

This design incorporates a dedicated Level 4 and clear bags sortation line, to allow for load sharing between the two screening lines. This increases the capability of the future rise in passenger numbers at the airport.

As part of this solution, Robson Handling technology proposed several technologies which provided Southend Airport with a more efficient baggage system, with reduced power consumption and easier maintenance. Central to this solution was the Robson Smart Line Controls System, a distributed, single line installation controls architecture which de-risked the installation phase of the project, allowing easier maintenance and facilitating the mobilisation of baggage operators.

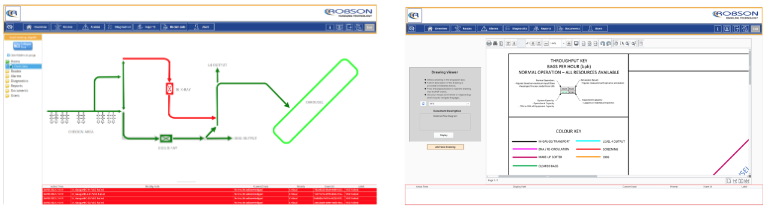

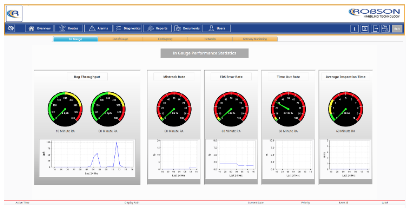

The latest Robson Handling Technology SCADA system was designed and tailored to suit the airport’s detailed requirements. The Robson SCADA system allows the airport to monitor and control the BHS locally as well as remotely; with this secured remote connection, the Southend team are therefore able to increase the mobility of the workforce and decrease the response time when it comes to acknowledging and rectifying issues in the BHS – all contributing to the reduction of cost due to system downtime.

2 Who are London Southend Airport?

London Southend Airport is the UK’s fastest-growing regional airport, with a rich history – and an exciting future.

Serving ca. 2 million business and leisure passengers in 2019, flying to over 50 destinations across Europe. The airport is quick to get to from Central London.

The airport is served by up to six direct trains an hour from London Liverpool Street, with journey times of approx. 52 minutes. Passengers can also get to the airport from Stratford Station in around 40 minutes.

London Southend Airport is just a short trip to the heart of the continent… and the heart of the capital London.

3 The New London Southend Airport System

The new system installed by Robson Handling technology features multiple upgrades to the mechanical and electrical components. This project has been designated to have an expected design life of more than 15 years.

Notable features installed:

- Ignition based Robson SCADA System for the departures area

- Innovative Robson Smart line Controls System

- Bespoke design for the departure friction drive carousel

- Incorporation of 2 Luffing conveyors to aid with efficient sortation of bags

- Installation of 60 plus baggage conveyors

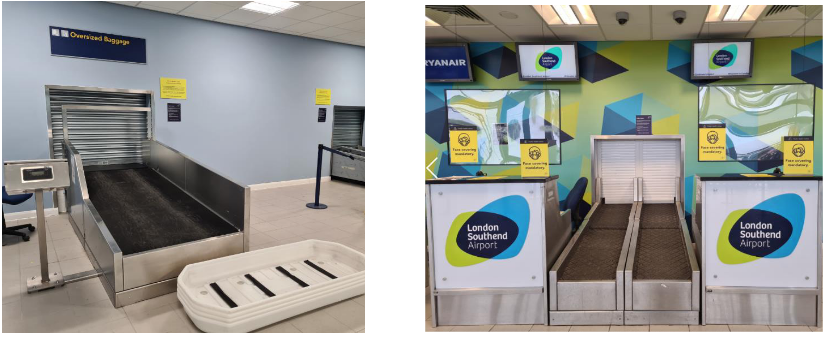

- 4 new bag-drop check-in lines with weighing scales

- Fitment of replacement control panels for 10 existing check-in desks to enable interfacing with the new system

- Strategical arrangement of check-in desk to allow facilities for a further 20 bag drop locations in the future.

4 Key benefits from investing in the new Robson system

Additional capacity and system resilience were both key drivers for the project. Aligning with London Southend Airport’s growth projections and system compliance requirements, the system delivers both additional check-in and EDS capacity. With this, the airport is able to minimise current capital investment as the new installation considers an efficient baggage design along with potential future expansions.

Furthermore, the system provides resilience in the case of EDS machine failure as the arrangement considers optional contingency routes to maintain operation with low impact to efficiency rates.

The new design introduces an increase of reliability within the system and improvements in worker safety; both of which result in higher customer satisfaction.

5 Latest technology / features installed on the new system:

5.1 Robson Smart Line Conveyor Control

All conveyors within the system take leverage of Robson’s advanced dynamic-speed control software as standard, optimising the bag journey in terms of energy efficiency, bag presentation, and journey time.

The benefits derived from the dynamic speed conveyor approach include:

- Advanced energy-saving modes, including an option to run the conveyors ‘on demand’ based on an analysis of system traffic undertaken in real time by the system.

- The ability to maintain efficient flow control and maximising throughput, with conveyor functions that utilise Dieback, gap, and pitch control.

- Over-length and dual bag separation.

- Use of Bag indexing techniques to accumulate bags on conveyors over three metres in length. This indexing increases the storage capacity of long conveyors and allow the upstream conveyors to continue supplying bags into the system to contribute to the high throughput rate.

- In-system time reductions based upon the concept of accelerating bags downstream wherever there is capacity.

- Dynamic injection speeds at merge points, which can be configured to impact upon bag orientation and/or prevent bag snagging on conveyor side walls.

- Automated bag toppling using Robson ‘Shockwave’ technologies.

- On command rerouting and priority capabilities with operator input.

5.2 Energy Efficiency

Permanent magnet IE4 motors are used on the solution which bring significant energy savings over IE2 or IE3 motors. Furthermore, the Robson software and dynamic speed control runs these motors in a more efficient manner further reducing emissions, as a result of lower power consumption.

5.3 SCADA System

The inclusion of a new SCADA upper-level system allows to maintain efficiency and avoid downtime through communication of system issues. The SCADA is accessible through local operator workstations and through an integrated VPN connection within the network. This connection allows remote troubleshooting for maintenance workers located off-site, therefore decreasing response time and cost for restoration of the system.

The SCADA monitors the entirety of the system and where necessary, permits control over operations. The function for control is permitted through a security base role-allocation arrangement on each user account. Enabling ‘operator’ user accounts to carry out manually operated procedures, whilst restricting ‘guest’ user accounts to viewing only (to avoid uncontrolled interference with current operations).

The design gives an intuitive look at the system’s real time condition and status. The alarm statuses are presented in a similar vein, giving the user a clear overview of any current active alarm. With this angle of perspective, the recovery time decreases through prevention of minor problems developing further.

To assist with ISA 18 alarm management compliance, the SCADA integrates a custom alarm notification profile that allows email-alerts be sent to designated personnel in the event of a critical alarm.

This SCADA includes a document viewing tool for sharing and storing relevant documents such as layout drawings, operator manuals etc. The file storage is kept within a self-contained and externally accessible database. As all users have access to view these documents it’s effortless to stay on top of revision control as well as avoiding the need for paper copies.

Custom reports are created thanks to the system’s real time data acquisition & the SCADA reporting module – giving rise to scope for efficiency & performance statistics.

5.4 Bag drop Lines

The design of the check-in desk is protected from unauthorised access via fire shutter doors.

The arrangement for the bag drop locations are fitted to facilitate a further 20 extra bag drop locations for future

installation.

6 Why Robson?

Robson / London Southend Airport have worked collaboratively for many years on previous projects, delivering baggage system projects on time and on budget. Over time London Southend Airport have come to trust Robson and the solutions we provide. Moreover, London Southend Airport trusted Robson to identify & integrate new technologies into the baggage system which improve efficiency and performance. During the tender phase, Robson demonstrated how the additional capacity could be achieved with the latest Robson smart line controls solution with SCADA integrating the highly efficient IE4 motors providing a dynamic and reliable sortation solution.

7 Project Timescales

This project had very tight timescales with challenging work areas (public and airside), with careful and collaborative

planning/ phasing engaging with the stakeholders throughout, the tight deadlines were achieved in total partnership.

8 3D Interactive tour

Please click to www.robson.co.uk for a system virtual tour, walk through a similar system also installed by Robson, exploring the latest technology installed at your leisure.

Contact

Coleford Road

Sheffield

United Kingdom

S9 5PA

- +44 (0) 1142 444 221