Docking & FAL Systems

| Company | CTI Systems |

|---|

Images

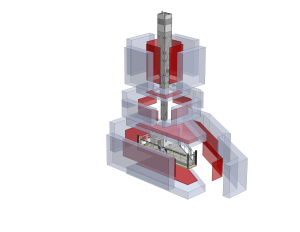

CTI Systems docking systems are used in aircraft maintenance and overhaul. By enclosing all relevant work areas on the aircraft, they allow simultaneous access and work in any desired work area, resulting in shortest possible turnaround times (TAT).

While on the one hand dockings must be ergonomic and stable in order to accommodate integrated fixtures or to be able to work on dismantled components close to the aircraft, on the other hand they should allow sufficient clearance to test movable components (flaps, rudders, doors, landing gears, etc.) in docked condition.

Ideally and in addition, they should be flexible enough to handle different aircraft types.

CTI Systems docking systems provide sophisticated solutions for all these requirements:

Integrated media supply such as compressed air, power and lighting are part of the standard repertoire. Motorized or manually adjustable working levels, flaps or platform sections, workbenches with IT connection, tank ventilation equipment, lifting aids, personal protection devices and much more complete the equipment and guarantee unhindered, fast work processes.

The dock systems are configured according to the customer’s requirements. This means that the maintenance areas can be covered individually or combined by

– Nose docks

– Wing docks

– Fuselage docks

– Tail docks

and many more complementary modules, all in different design variants and adapted according to the desired work processes and the local hangar environment.

The wide range of variants and applications has led to CTI Systems’ docking systems also being used by renowned OEM aerospace companies in several final assembly lines.

WiFi Docks

The WiFi Dock from CTI Systems is a special work platform that provides safe access to the upper areas of the aircraft fuselage for easy access to the WiFi antenna and similar parts.

For easy and safe movement and positioning on the aircraft, the top safety surround swings up. Once positioned on the aircraft, it is lowered safely by its buffers at the bottom edge, thus securing the work area against falling.

This particular dock is fully height adjustable and allows access to both the antenna area and the interior of the aircraft to perform the necessary work.

The WiFi docks consist of two or three modules, depending on the type of aircraft, and are suitable for both Narrow and Wide body aircraft.

Tail XS Dock

The innovative CTI Systems’ Tail-XS provides maintenance and service engineers with access to the aircraft’s VTP stabiliser. Particularly suitable for hangars with restricted ceiling heights, the Tail XS dock uses integrated multi-level tail dock technology in combination with a CTI Systems teleplatform.

All necessary media and tools can be provided to different platform levels, as required to guarantee the ultimate flexibility when working on the aircraft’s vertical tail plane.