Check-in systems

| Company | Robson Handling Technology |

|---|

Images

Robson Handling Technology provide a complete range of airport check-in system options.

From conventional staffed check-in desks and bag-drop kiosks to fully self-service Bag Tag and Bag Drop units, including an option to deploy remote Bag Tagging facilities in off-airport locations.

Designed and built with the passenger experience in mind, our airport check-in systems are purposely designed augment a seamless and stress-free passenger journey. Our systems provide full track and trace functionality via an automated delivery system.

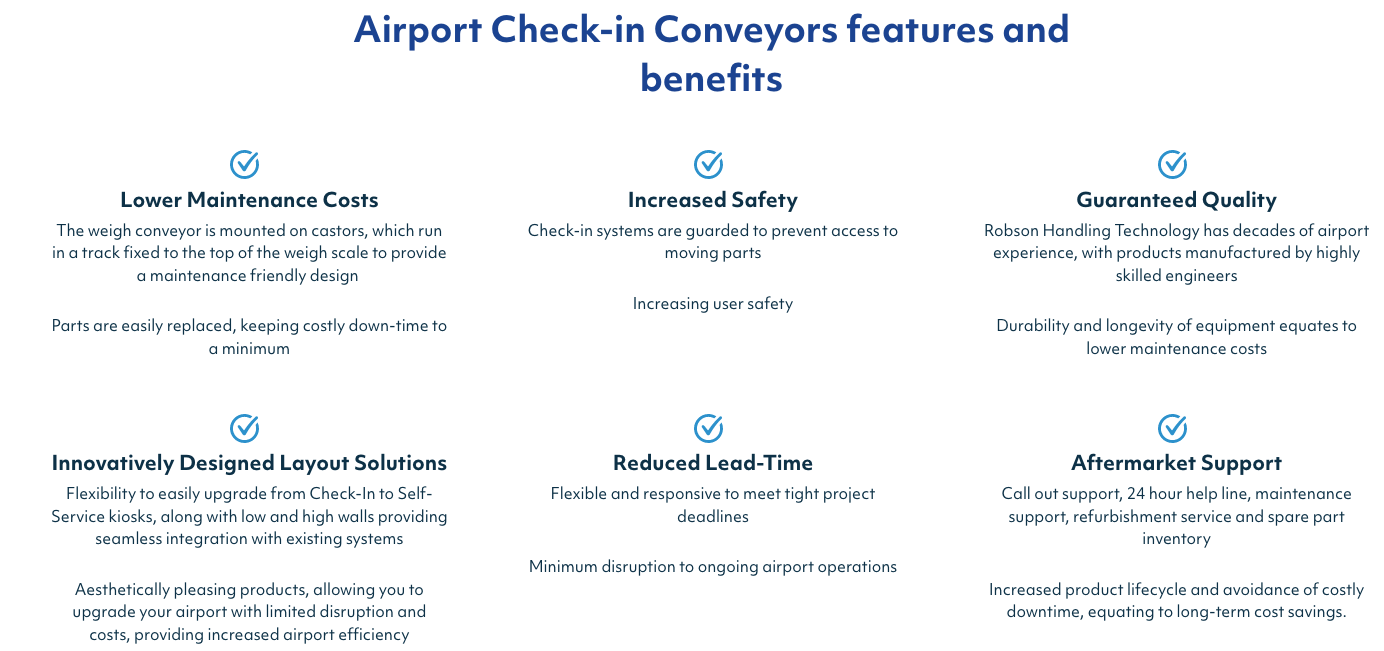

Using the latest automation technologies, our systems provide a range of benefits:

- Full Integration with the baggage handling system

- State of the art designs to match the surrounding environment

- Ergonomically friendly

- Optimised use of space

- User friendly operation

- Easy servicing and maintenance

- Bag Tagging in off-airport locations

Creating a positive passenger experience

Our airport check-in units provide:

- Fast, accurate, and trouble-free check-in processing for passengers and their baggage

- User friendly, easy to use self-service and remote tagging systems

- Smart solutions dependent on passenger densities

- Integrated bag delivery from other locations