Ammeraal Beltech

Airport Process and Conveyor Belting

Ammeraal Beltech is one of the world’s leaders in Airport Process Conveyor Belting. You will find our belting products at all the major airports around the world.

Passenger baggage is a vital aspect of airport management, and how quickly, safely and accurately it moves around will directly influence overall airport efficiency and consumer satisfaction. Ammeraal Beltech belts are providing outstanding service in airports around the world.

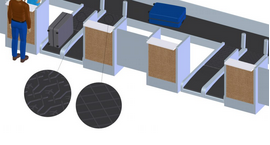

Check-in and Weighing

Ammeraal Beltech Check-in Belts are used in departure areas of airports around the world. Check-in and weighing systems require special properties. Our belts have profiles especially suited for the transport of roller suitcases.

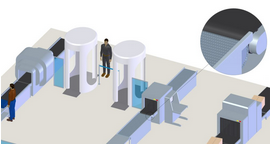

Hand Baggage Control

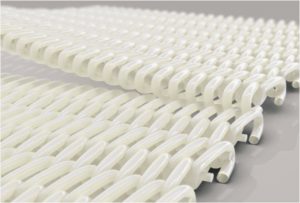

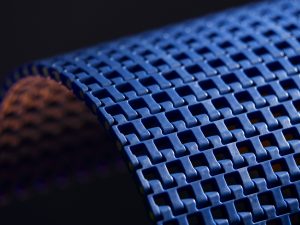

One of the most vital steps in airport and aviation safety. Pre-departure security check, baggage screening and explosive detection systems are of paramount importance. Uni Modular Belts offer flexibility and quality and Flexam plied Synthetic Belts support passenger convenience (low noise).

X-Ray Scanning

One of the most vital steps in airport and aviation safety. Pre-departure security check, baggage screening and explosive detection systems are of paramount importance. Flexam Belts offer flexibility and quality. Our screening belts prevent breakdowns.

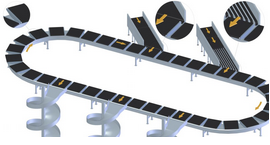

Sorting - Cross Belt Sorters

Baggage sorting involves high speed conveyors equipped with cross-belt and tilt-tray sorters to minimise transfer times. We can offer long wearing top covers with excellent grip properties. Flame-retardant according to ISO340!

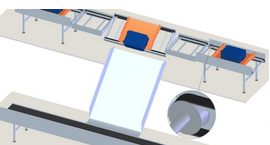

Sorting - Tray Systems

Ammeraal Beltech offers innovative solutions for intelligent sorting and tray sorting systems. Strong belt construction and belt coatings (together with profiles designed for grip). No elongation of the belt also means there is no need for re-tensioning on most applications.

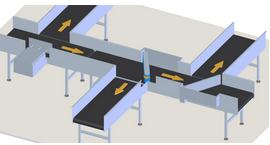

Sorting - Pushers and Dividers

Ammeraal Beltech quality ensures maximum service life. Pullers, pushers, merging facilities – all of these processes require belts that have special coatings to guarantee the firmest possible grip and smooth transport of luggage. Our impact resistant Flexam Belts are an industry favorite: Flame-retardant according to ISO340, no elongation of the belt thus no re-tensioning needed on most applications.

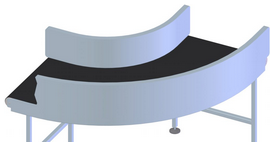

Transportation - Curve and Take-Away

Curved Belts must be able to handle heavy loads and transport luggage smoothly. Our extra-strong Curve Belts can handle loads up to 250 kg. Low noise yet strong belts, capable of high speeds.

Transportation - Merge, Take-Away and Vertical Sorting

Merge Conveyors are designed to queue baggage within a system, precisely adding bags from one conveyor line to another at high rates of speed. Our belts offer low coefficient of friction bottom covers. Our Merge Belts are engineered to provide efficient and accurate merging of various baggage sizes and can cycle up to 60 bags p/m.

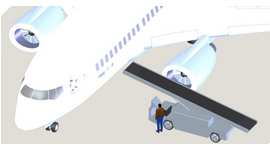

Loading / Unloading - Belly Loading

A critical step performed in varying, often extreme weather conditions. We can offer impact resistant and high grip belts which are weather and temperature resistant and can have Anti-static properties.

Arrivals Claim

The final stage of the Baggage Handling System journey – baggage is delivered to passengers. Reliable, low noise and fire resistant belts with lateral stability for perfect tracking!

Company Profile

WE MAKE YOUR SUSTAINABILITY MOVE

Prioritizing sustainable supply chains is crucial for businesses aiming to reduce their environmental footprint and adopt responsible practices. Opting for eco-friendly solutions not only enhances your airport’s sustainability rating but also contributes to bolstering your brand reputation.

At Ammeraal Beltech, we take our social responsibility seriously and strive to continuously improve our products, services, and solutions for the benefit of society, the environment, and your business.

Our vision to be the local partner of choice for sustainable belting solutions is becoming a reality. In 2023, our performance in corporate social responsibility earned us a gold medal from EcoVadis, placing our company at the top of the rating.

Furthermore, as a member of AMMEGA Group, Ammeraal Beltech is a signatory of the United Nations Global Compact, committing to meet fundamental responsibilities in four areas: human rights, labor, environment, and anti-corruption.

What can we do for the airport industry?

With expertise in the airport sector, we offer top-tier solutions for:

- Energy Saving

- Lowest power consumption and operating costs for airports of all sizes

- Low Noise for environmentally friendly working conditions

- Minimized maintenance and downtime

- Flame retardant and antistatic to minimize (fire) hazards

- Abrasion and temperature resistance; weather-proof for reliable operation

Explore the market’s most energy-efficient conveyor belt!

Our innovative solution seamlessly merges energy-saving design with cutting-edge recycling technology, utilizing a special fabric crafted from recycled PET bottles. Rigorously tested at Heathrow Airport, it has earned testimonials attesting to its outstanding performance and sustainability features.

Discover our sustainable innovations here! Contact us to elevate your operations with eco-friendly efficiency!

Products

ZipLink®

Lightweight Rubber Belts