Blastrac

To Prepare & Maintain Surfaces on Airport Terminals, Aprons & Runways

SURFACE PREPARATION TECHNOLOGIES FOR AIRPORTS & RUNWAYS

The future of airport surfaces maintenance is the adoption of a “Tool Box” approach to the various scope of work necessary at today’s airports. Managers and maintenance crews will need a variety of equipment to keep pavement surfaces in the safest and best conditions to meet the demanding standards of the 21st Century.

Blastrac is the leading global developer and manufacturer of surface preparation equipment. We have an extensive range with over 80 different machines for preparing & maintaining floors and other surfaces for all kinds of materials. Our innovative techniques are developed in-house and on demand by our strong R&D department.

Blastrac surface preparation equipment can be used on airfields for:

- FRICTION IMPROVEMENTS & RUBBER REMOVAL

- MAINTENANCE OF LINES & MARKINGS

- SURFACE PREPARATION FOR CAR PARKS, HANGARS, WAREHOUSES

- DECORATIVE SURFACES | GRINDING, POLISHING & BUSH-HAMMERING

- GENERAL CONCRETE MAINTENANCE

Blastrac Green Technologies

All Blastrac technologies are purely mechanical and therefore very clean. None of our technologies create air pollution or use chemical substances. With all our equipment you are also able to work dust-free, meaning that each machine can be connected to a Blastrac dust collector which will collect all the dust and other small hazardous particles that are released during the surface preparation process. This creates a safe working environment!

Company Profile

Friction Improvements & Rubber Removal

The condition of the runway surface is important when you are looking to improve airfield safety. There are many elements which can affect this such as: structure, materials used, surface type, snow, ice, water and contamination from various sources (especially from rubber deposits).

Regardless of the pavement type, runway friction characteristics will change over time depending on the type and frequency of aircraft activity and weather conditions. In addition to ordinary mechanical wear and tear from aircraft tires, contaminants can collect on runway pavement surfaces which decreases their friction properties.

Accidents and near accidents can occur from planes overshooting or veering off contaminated runways. It is therefore essential to maintain the airport runways to the highest possible standards and to ensure adequate surface drainage and grip, especially in areas of take off and landing.

Blastrac continues to develop technologies in order to reduce the braking distance of airplanes. Over the years we have developed different technologies to maintain the runways.

Retexturing the surface by applying shot blasting technology has been repeatedly demonstrated to be an important key for successful friction improvements.

Removal of Excessive Rubber from the Runway – Shot Blasting

As aircraft landings take place, the traffic wears down macro-texture and micro-texture as contaminants build up on the runway pavement. This build-up of rubber will decrease water drainage and friction to the point where safety may be diminished. Removal of excessive rubber from the runway is to maintain safe operations.

A very efficient and cost effective method for removing rubber deposits from a runway is shot blasting. It removes contamination such as rubber and at the same time retextures the surface to provide a clean, skid resistant, free draining runway to land for aircrafts.

Machine productivity (rubber removal square meters per hour) is another important consideration. Shot blasting technology doesn’t need any valuable drinking water to work so it can also be used in areas where fresh water supply is an issue. In addition, shot blasting is the only technique which is able to regenerate both the micro and the macro textures of the surface.

RUBBER DEPOSIT REMOVAL FREQUENCY

AIRCRAFT LANDINGS PER DAY RUBBER REMOVAL FREQUENCY Less than 15 2 Years 16 to 30 1 Year 31 to 90 6 Months 91 to 150 4 Months 151 to 210 3 Months Greater than 210 2 Months

There are principally 2 types of texture which are important factors in the performance of runway surfaces: Macrotexture & Microtexture

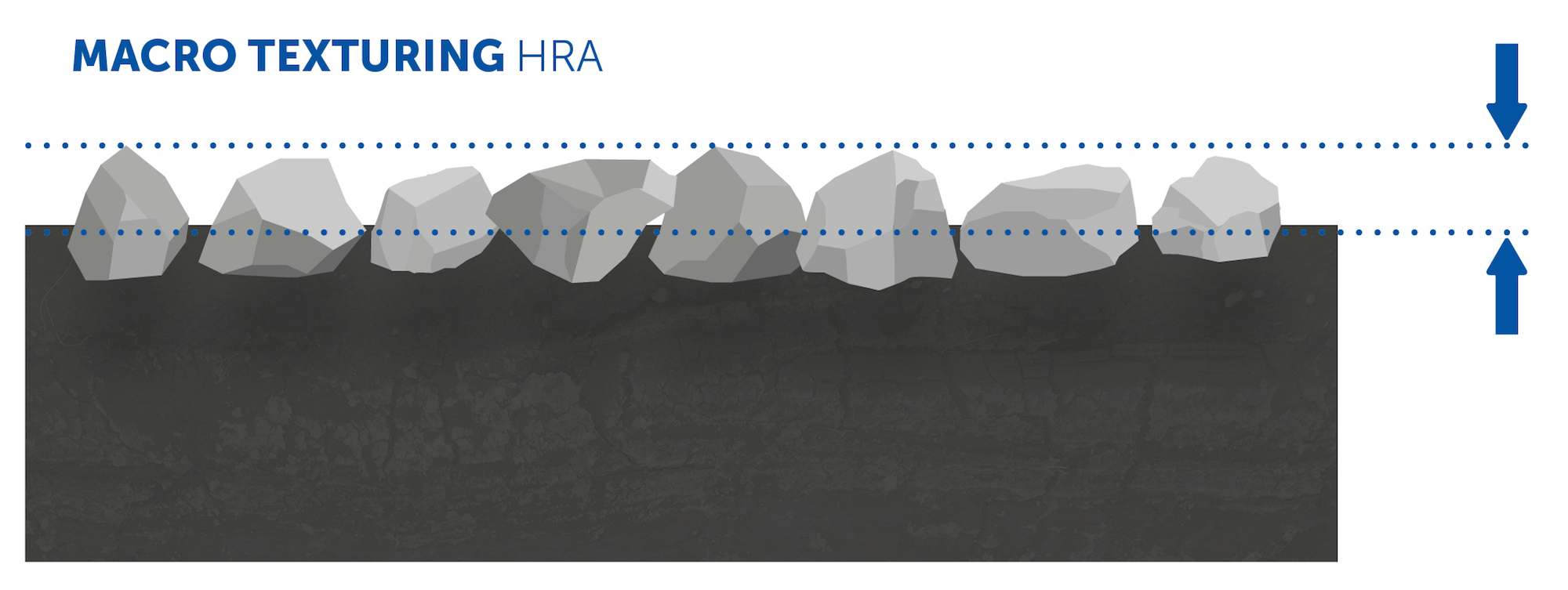

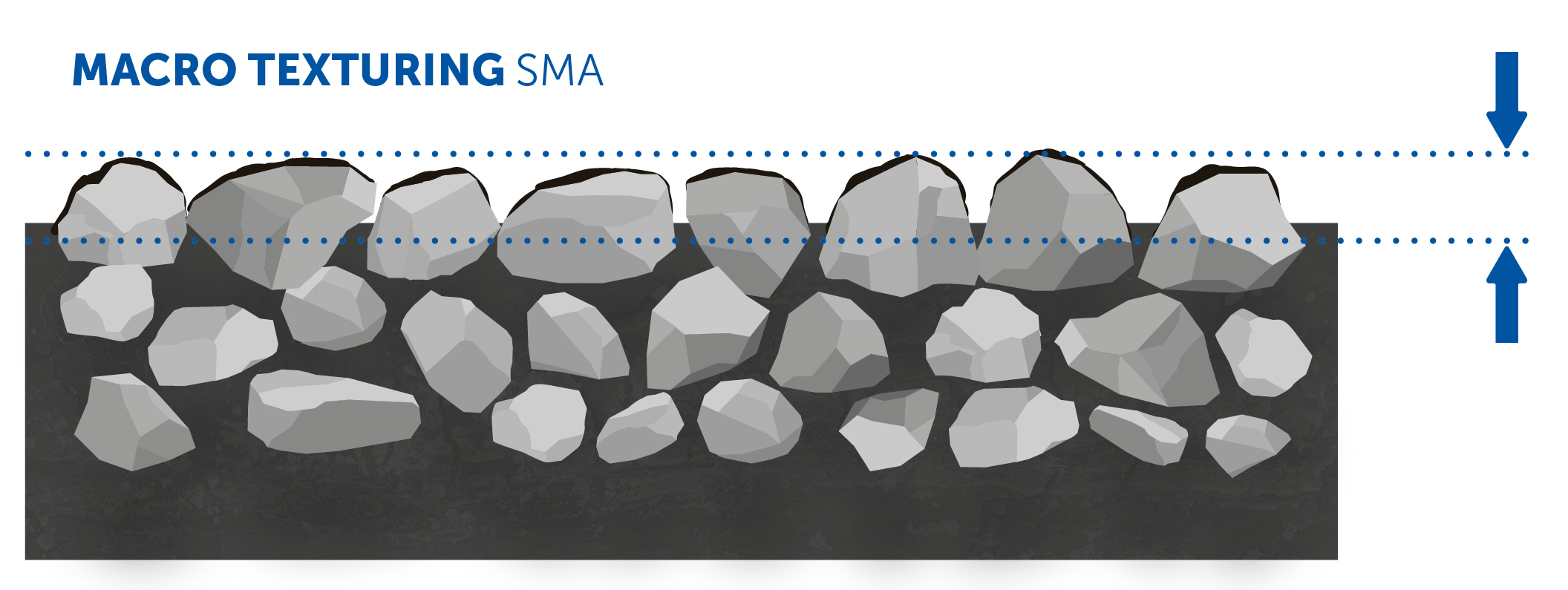

MACROTEXTURE is the space or voids between the aggregate particles.

The texture depth / macro texture of an asphalt pavement surface will normally be between 1.0mm to 1.5mms. It is this macrotexture which allows the water to drain away from the surface and greatly contributes to skid resistance in wet conditions.

Shot blasting is a very cost effective, environmentally friendly and high performance technology for improving the macro texture of a surface. It will remove rubber dirt deposits and will bring the surface Macrotexture back to that of the aggregates ability. Macrotexture can be measured by laser profilometers traveling at normal speeds.

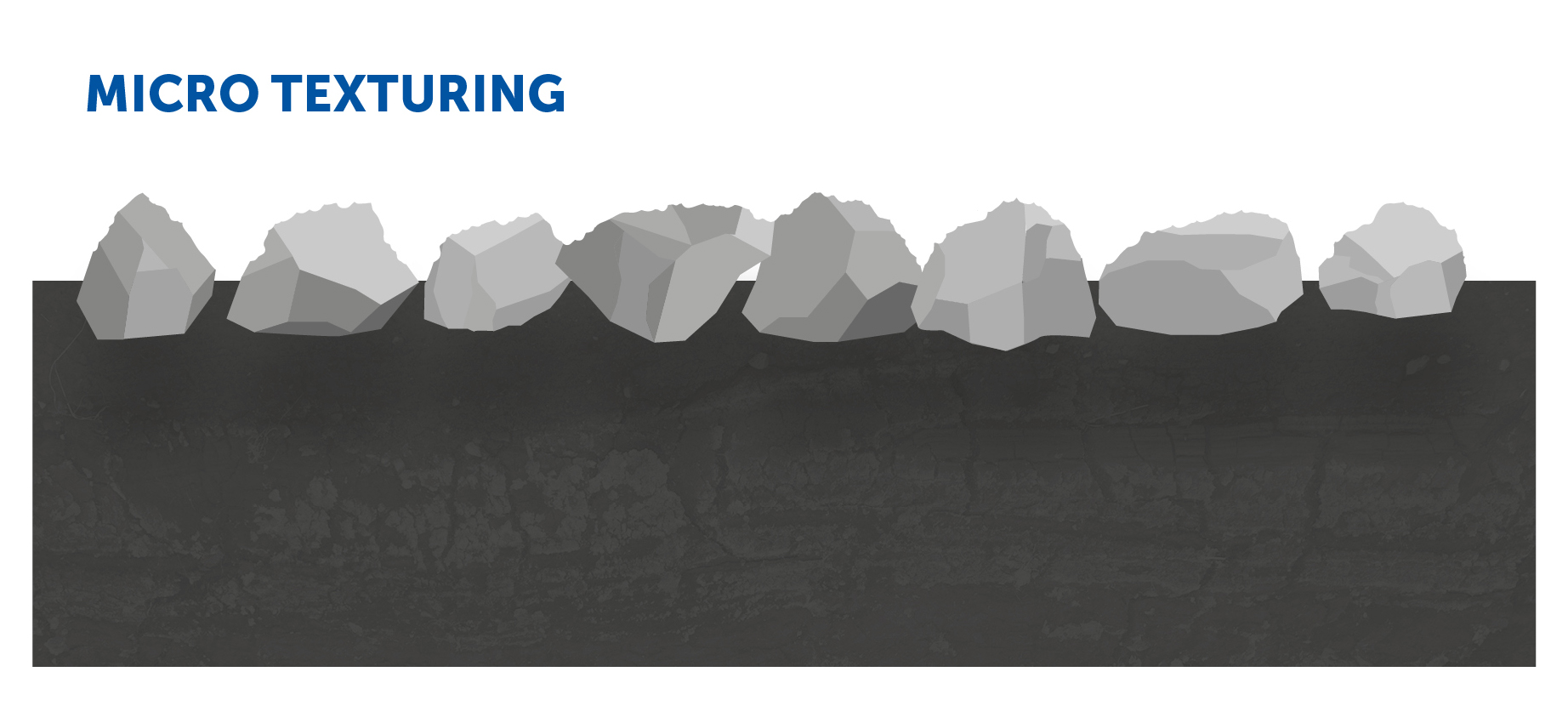

MICROTEXTURE is the fine component of surface texture formed by the tiny interstices on the surface of the aggregate particles.

It is the main contributor to providing grip or skid resistance with the tyre, particularly at low speeds. Microtexture is measured by PSV using the British Pendulum Tester or by mobile methods such as the Griptester or SCRIM.

Shot blasting is the only technology that will restore Microtexture values to pavement surfaces. Improvement of Microtexture with the shot blasting process is extremely effective. It will in all cases bring back the full benefit of the PSV of the aggregate as per its original properties.

Maintenance of Lines & Markings

In the past Blastrac have received numerous requests to develop a fast and effective solution for the removal and maintenance of existing line markings. Airport maintenance contractors worlwide are searching for environmentally friendly machines which are more mobile to remove or clean markings on airfields pavements (Runways, Taxiways, Aprons & Paved Airfield Roadways)

Nowadays the two main standard application materials for marking lines are thermoplastic and cold paint.

Thermo-plastic Line Removal | Scarifying & Grinding

Because of its thickness and flexibility, thermoplastic is not an easy material to remove. The best method to do so is to use a scarifying or a grinding machine. Both techniques remove markings in a very efficient way without damaging the pavement or asphalt.

Blastrac scarifying machines are extremely suitable for line marking removal of thick / elastic materials such as thermoplastic. Due to their micrometric and memorized adjustment for the working depth, it makes sure there is no deterioration beneath the surface. In addition, the surface is immediately ready for applying new markings.

Blastrac grinding machines is another option to remove thermoplastic lines in an efficient way by using PCD tools. Polycrystalline Diamond (PCD) is a very hard material and is abrasive resistant in all directions. It doesn’t damage the surface and carry out a clean result, free of dust.

Cold Paint Line Removal | Shot Blasting

Cold paint is much easier to remove than thermoplastic because of its thinness and properties. Blastrac shot blasting systems are highly effective in removing thinly painted striping and line markings on roadways and parking surfaces. For most of our shot blasters, we’ve developed blast pattern reducers to reduce the working width.

Blastrac shot blasting technology leaves the surface clean and dry, which means that it is immediately ready for new painting or other surface treatments. The surface does not get damaged by the shot impact and it doesn’t leave any dust on the floor. Shot blasting is purely mechanical and there is a wide variety of sizes and models available.

Line Cleaning | Grinding

Because aircrafts’ tires produce waste material and other contaminants, line markings on airfields get dirty. Instead of removing these markings before applying new ones, the new trend is to clean the lines.

We have developed a process to clean the marking lines with a single disc grinder equipped with polishing pads. It is the perfect solution for line cleaning operations. It is a small and very mobile equipment that use resin pads to clean the lines, without damaging them, thus preserving their lifetime. The single disc grinding machine must be connected to a dedicated dust collector in order to ensure dust free operations.

Surface Preparation | Creating a Surface Cohesion to Apply Paint & Markings

Depending on the floor you have to prepare; a wide variety of profiles can be carried out. Shot Blasting is the perfect method to prepare the surface and to ensure a surface cohesion before applying paint, markings and line materials on concrete and asphalt surfaces. For further information about alternative techniques please do not hesitate to get in touch with us!

Surface Preparation for Car Parks, Hangars Warehouses...

Surface Preparation is defined as the complete removal of the laitance or cream coat of the concrete. By doing so we are opening up the capillaries of the concrete. This allows the material that is being installed to wick into the pours of the slab allowing it to establish a mechanical bond. The surface preparation process is the key for long lasting coatings in car parks, hangars and warehouses…

There are three main surface preparation methods: grinding, shot blasting and scarifying. These three techniques require dust collectors equipped with endless bagging systems in order to protect operators from hazardous dust. Blastrac, as a specialist of surface preparation equipment, offers a wide range of shot blasters, single disc and triple disc grinders and scarifiers for the surface preparation industry. Get in touch with us for more information.

Concrete Surface Profiles (CSP) | CSP-1 To CSP-10

There is a governing body called the ICRI (International Concrete Restoration Institute) that set surface profile standards over the industry. They created concrete surface profile or CSP samples using different preparation methods. These methods were then given a rating system from 1 to 10. Some technologies can achieve multiple profiles while others can only produce 1.

Depending on the coating to be applied, the manufacturer of that product will specify a desired concrete surface profile (CSP) which has to be adhered to. Every manufacturer in this industry has tied a CSP profile to all of their products. This ensures each system has the correct level of profile to ensure proper adhesion to the slab.

If the surface preparation has been carried out properly, the manufacturer will provide a warranty with that product.

Decorative Surfaces

The use of colours and natural finishes is now without doubt an extremely important element in the modern construction and landscaping of airports. To satisfy this demand for decorative surfaces, Blastrac have developed various methods to carry out a lot of different decorative flooring solutions.

Depending on the basic material of the surface (concrete, asphalt, terrazzo, marble…), it is possible to carry out a wide range of decorative surfaces with Blastrac equipment. From polishing, bush-hammering, to exposing aggregates on the surface, anything is possible!

General Concrete Maintenance

The airport apron is the area of the airport where aircrafts are parked, unloaded or loaded, refueled or boarded. Apron is typically more accessible than runways or taxiways, which gives more opportunity for regular maintanace. Most of the time, the apron surface is made of concrete.

General Concrete Maintenance | Full Range of Blastrac Equipment

Blastrac equipment enables you to carry out any operation related to apron surface maintenance, whether it is cleaning, leveling or maintaining surfaces. Depending on what you have to do, you have to select the correct equipment.

Wherever there are pavement or concrete surfaces, there are general maintenance requirements. This could include the leveling of floors, repair of cracks or the removal of bumps.

Mobile shot blasters, single disc grinders, triple disc grinders, scarifiers, and milling machines are great tools to have on hand for accomplishing these maintenance projects. Paired with approved (HEPA) dust collectors, these machines eliminate clean up and protect airport employees from airborne contaminants. For further information about general maintenance on airports, please do not hesitate to get in touch with us!

Products

Images

Contact

Utrechthaven 12

3433PN Nieuwegein

Netherlands

- +31 (0)30 601 88 66