JLC Group

Fire & Security, Access Control, Aviation Ground Power, Electric Vehicles and Custom Covid Solutions

JLC Group are a multidisciplined UK engineering company designing, installing and maintaining specialist systems ranging from bomb blast doors, intelligent access control systems, to fixed electrical ground power. With over 200 years of experience in producing solutions for complex problems, our in-house design and manufacturing allows us to create custom products for our clients.

Our wealth and experience, combined with comprehensive training and a continuous professional development philosophy enables us to provide a high quality service that we continually strive to improve and enhance.

We work all over the UK providing and installing the best equipment from our suppliers around the world. JLC can service and maintain products such as automated doors and entry systems, fire shutters, fire rated sliding doors, blast enhanced automated sliding doors, access boarding gates, one-way security doors/anti-walk-back, occupancy control system, body temperature control systems, crocodile cable carriers, alligator cable carriers, output cables, ground power units and supplies, pit systems, aviation cable lanyards, aircraft connectors, electric vehicles and electric vehicle power supplies.

As an independent company, we are not bound to any manufacturer, which gives us the flexibility in sourcing world class products and systems that are not only tailored to our individual customer’s premises and requirement, but also cost competitive. We offer free site surveys and no obligation quotations, please complete our enquiry form for further information and to request a call back.

Company Profile

-

Ground Support Equipment

Aviation ground power supplied, installed & maintained by… | JLC Group (jlc-group.co.uk)

We are able to provide the airside environment with world-class ground power units, premium quality 400Hz cabling, and reliable Cable Carrying Alligators that are built to last.

Fixed Ground Power

We work closely with GPU manufacturer ITW GSE to provide the best possible solution to aircraft ground power. ITW GSE has a comprehensive knowledge of controlling and optimizing ground power units, and are the trusted GPU provider to a vast number of airports, both in the UK and internationally. These units offer unrivalled reliability and safety, while ensuring the airport runs smoothly with its fast installation and quick maintenance.

Ground power cables and cable carriers

JLC has consulted with airside operations engineers to manufacture and produce a safe, robust cable carrier that is designed to meet the needs of the crews that operate them. Our cable carrier integrates ‘knuckles’ into its design to ensure the protection of the high voltage cables during periods of movement, therefore providing the cable with a longer lifespan. The cable basket itself is built to withstand both environmental threats and negligence of use, and all areas of the structure are designed to perform under pressure.

The JLC FEGP (fixed electrical ground power) cables have been designed to be more robust and durable than other aviation cables currently available. They are ideal for use on ground power cable carriers (Alligators) retaining high flexibility even under the influence of ozone, light, oxygen, protective gases, oil and petrol.

Servicing and Maintenance

JLC Group provides a comprehensive range of ground power unit servicing and maintenance packages for all types of GPU equipment, ensuring the equipment is always operating reliably, efficiently and safely. Our maintenance programmes include inspection, repair and remedial work, plus the provision of replacement cables, connectors and spare parts. To minimise the downtime in operation, a GPU service can be carried out on-site by JLC’s experienced and fully trained team of service engineers.

Benefits of Working with JLC Group on the airside include:

-

- Over 200 years’ experience in airside GSE manufacture and maintenance.

- A trusted supplier at many UK Airports, including Gatwick, Heathrow and Glasgow.

- The UK’s official servicing agent for the world’s leading GPU supplier, ITW GSE.

- A focus on the quality of our products and the safety of airside operators.

- An aim to service and repair in a timely fashion, no matter the fault.

-

-

Automated Access Control – For all areas of the Airport

JLC Group’s Land side operations include the supply, install and maintenance of automated entrance systems, including doors, barriers and gates, that offer ease of use and access control, without compromising security. Our Automated solutions are extensive, and include:

One-Way Security Corridors

Working in partnership with Manusa, JLC Group offers the Touran range of one-way security corridors (also known as anti-walk back systems). These automated systems are specifically designed to only allow one-way pedestrian access or egress, particularly to secure areas, such as those at airport, and removes the need for a security officer in these areas.

The Touran operates using two sets of interlocking doors that open automatically in the direction of traffic, allowing movement one way but not the other. In the event of a stationary item or movement in the wrong direction, sensors are able to alert a controlling officer and close the door, preventing unauthorised movement.

Along with installation, JLC Group also provides the maintenance of these door systems. Anti-walk back corridors have become an essential security system in many areas of the airport, and we are proud to be Manusa’s official supplier in the UK.

Access boarding gates

To compliment the Touran, JLC Group supply, install and maintain Access Boarding Gates throughout the UK. This access control system is designed where safety and user comfort come first. The system consists of slim, elegant modules that support swinging glass panels that open according to the direction of transit and can be managed by any access control system.

-

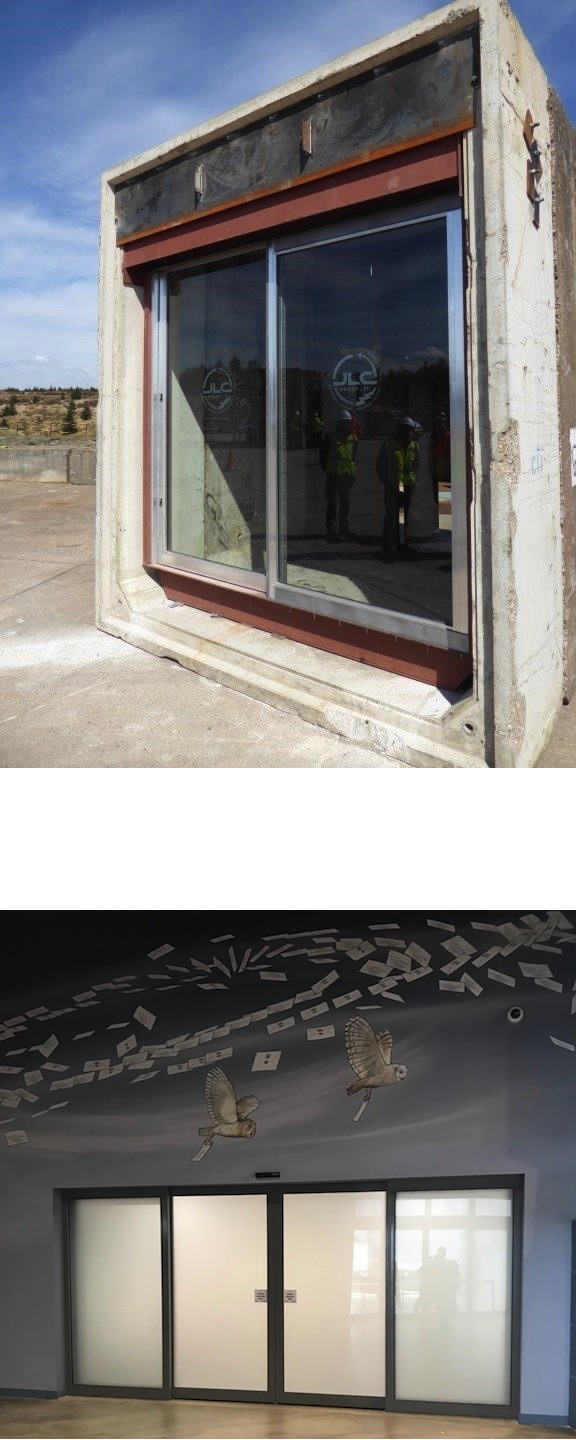

Blast Enhanced Automatic Sliding Door Systems

Our blast-enhanced sliding door system combines the key properties required for blast protection with aesthetically pleasing and spacious design of any entrance door system, allowing for high levels of blast protection whilst maintaining the appearance of the building entrance or facade.

In line with the ever growing international demand for blast enhanced products, the detailed design of our blast enhanced sliding doors meet blast-mitigating standards in new and improved ways.

Key Advantages of the system properties are:

-

- Extremely robust design optimises operational reliability,

- Door system still meets all BS EN 16005 safety regulations,

- Largest sliding door system tested to ISO 16933 EXV25 blast classification,

- Purpose designed retaining sections to increase structural integrity,

- Various design choices & technical options available.

- Doors able to be manually operated with ease following a blast – allowing for emergency services to enter and/or peoples to avoid being trapped.

Tested to highly demanding requirements.

Our product development and testing is carried out in accordance with the most demanding standards.

The EXV25 / 100Kg TNT blast is designed to replicate a car bomb with a peak reflected pressure of 80kPa. You can gauge the magnitude of the blast in our video from the test.

Our design also includes additional features to aid in ensuring life and property remains sufficiently protected.

Large High Performance Entrances

Combining enhanced robust sliding door operators with a highly reinforced aluminium door system, our unique design allows for maximum clear opening sizes beyond the capacity of any other comparable system. Additionally the increased weight of the enhanced door system does not hamper the efficiency or reliability of the operator.

Door Performance

The design specification and practical build of the sliding door systems means that when subject to a blast, the entire profile has a large amount of flex preventing the fracture of glass and warping of the profile. The full performance of the door system can be seen in 2000 fps.

-

Products

Electric Van / ECO Van

Videos

Images

Contact

Unit 4 Nabbscott Farm

Eastbourne Road

Lower Dicker

Sussex

United Kingdom

BN27 4BB

- 0800 170 1515