IE5+ synchronous motors in a new size

| Company | NORD DRIVESYSTEMS |

|---|---|

| Date | 12.02.2026 |

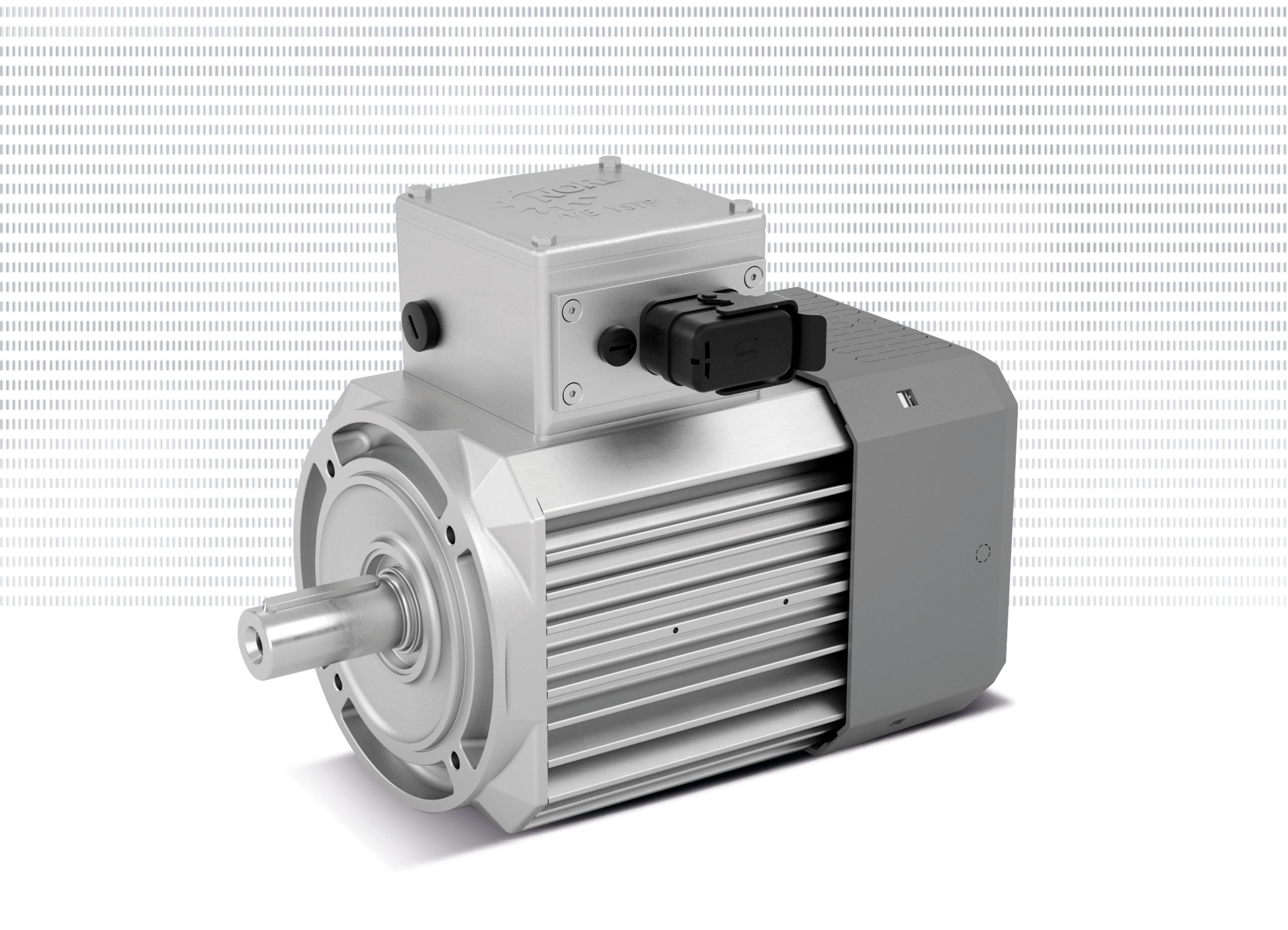

IE5+ synchronous motors from NORD are particularly sustainable thanks to their efficiency in terms of energy and material. Image: NORD DRIVESYSTEMS

Power extension for high-efficiency drives

With its latest IE5+ motor generation, system provider NORD DRIVESYSTEMS offers high-efficiency solutions to reduce energy and resource consumption in industry. The company has now extended the power of its compact permanent magnet synchronous motors to 11 kW.

NORD’s high-efficiency IE5+ permanent magnet synchronous motors (PMSM) are characterised by a constantly high efficiency of up to 95% over a wide torque range. They therefore achieve an optimum energy consumption performance in partial load and speed ranges. The motors are now available in three sizes and cover a wide range of applications with their extended power range from 0.35 kW to 11 kW and continuous torque from 1.6 Nm to 43.9 Nm.

The high overload capacity, the large adjustment range and the constant torque of the IE5+ motors over a wide speed range of up to 2.400 rpm enable variant reduction in the respective application, significantly streamlining administrative effort as well as manufacturing, logistics, storage and service processes. “Particularly in spacious intralogistics systems with many drives and long operating times, this provides significant advantages”, highlights Jörg Niermann, Head of Marketing at NORD.

Energy efficiency and material savings

“The efficiencies of our IE5+ motors significantly exceed the highest defined energy efficiency class, which considerably reduces their energy consumption and CO2e emissions”, Niermann adds. “In addition, the holistic concept of our new motor technology combines energy and material efficiency, thus scoring twice in terms of sustainability”. The permanent magnet synchronous motors feature 8 poles in an innovative IPM design. This allowed a reduction in the size of active motor parts, resulting in material savings in the sheet metal package and with regard to the magnets. The stator can also be manufactured with the so-called single-tooth winding, which reduces the use of copper in the winding head.

System solutions from a modular system

Drive solutions from NORD are tailored to the respective customer requirements and are suitable for worldwide use. For example, IE5+ motors are available with a motor-integrated encoder, an integrated mechanical brake and various flange mountings for direct attachment to a gear unit. Furthermore, the manufacturer enables the assembly of optimally matched drive systems, including electric motor, gear unit and frequency inverter from its extensive modular system – such as IE5+ motors in combination with NORDAC ON or a UNICASE helical bevel gear unit. In any case, the user benefits from increased operational efficiency, reduced total cost of ownership (TCO) and fast return on investment (ROI).

Contact

Member of the NORD DRIVESYSTEMS Group

Getriebebau-Nord-Straße 1

D-22941 Bargteheide/Hamburg

Germany

- +49 4532 289 - 0