Asphalt and Concrete Joint Sealant

| Company | Zel-Aaren / Swedish Net |

|---|---|

| Product code | PMS-4 |

Images

Time is tightening and a valuable resource therefore PMS-4 was designed as a sealant for specialized works in the airfields curing within only 2 minutes.

The Pur Moulding System, PMS-4, is a cold applied two-component polyurethane system of solid type suitable for the fixing of items in asphalt and concrete surfaces. With airfields being the largest customer base today, PMS-4 is also suitable for roads and bridges.

PMS-4 is manufactured in Sweden and used at airports in more than 20 countries all over the world, primarily to fix inset light bases or seal cable chases in taxiways and runways. The product has a very high thermostability (>100 °C), which together with a great impact resistance, is an important factor to keep items in a fixed position when the ground temperature is high. It needs only a few minutes of curing time before it can be driven upon. With the PMS-4 moulding method, the bases are kept in a fixed position in all climates, without sinking or twisting.

PMS-4 MACHINE

Application of the compound can be done with Zel-Aaren’s semi-automatic mixing machine.

The PMS-4 mixing machine is composed of two gear pumps, gravity fed with material (PMS-4) from two tanks containing the A component and the B component. The pumps charge the A + B component to the right proportions through two pressure safe tubes to a pistol nozzle which is equipped with a mixer pipe mixing the two components into a homogenous plastic mass, which then is cured within two or three minutes. The machine is designed and manufactured in Sweden.

PMS-4 TRAINING

With the purchase of a PMS-4 moulding machine, Zel-Aaren also provide practical and theoretical training on-site to learn how to operate the machine for a satisfactory result.

For customers who already own a moulding machine, we also offer training material or site visits to help getting the best results.

Material Data

| Density | 1,1kg/lit |

| Potlife | 60-100sec. |

| Thermostability | >100°C |

| Impact stability | 45KJ/m² |

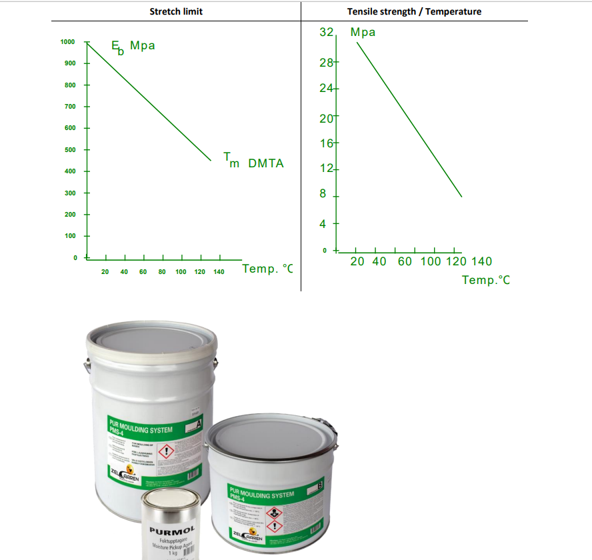

| Tensile strength/ temperature | see separate graph. |

| Bending module | see separate graph. |

| Stretch limit 23°C | 9-10 % |

| 60° | 14 % |

| 90° | outside the extensiometer limit |

| Coef. Of lin. Exp. 10-5°C-1 | 13,2 |

| Coef. Of cub. Exp. 10-5 °C-1 | 39.5 |

| Adhesion to steel | app 9Mpa |

| Adhesion to Concrete | >2,5Mpa ( concrete break ). |