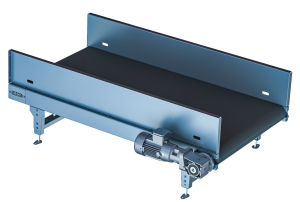

Baggage Belt Conveyor

| Company | BELTCON |

|---|

Images

Reliable quiet operation and Easy maintenance.

A Baggage belt conveyor is a type of material handling equipment used in various industries to transport goods, products, materials or baggage from one point to another. These conveyors are essential for automating logistics processes and increasing efficiency. It is Designed and developed for quiet operation, Easy access for maintenance, Configurable to suit building layout and system design requirements, seamless and ergonomic design.

BELTCON offers standardized and customized Baggage conveyor solutions to satisfy the material handling requirements for various industries. Below are the key components/Specification associated with Baggage Belt Conveyor that Beltcon properly chosen and manufactured for the conveyor assembly:

- Belt: The conveyor belt is the central component of the system. It consists of a continuous loop made of various materials such as rubber, fabric, or plastic. The belt moves along a set of rollers or pulleys, carrying the materials from the loading point to the unloading point. The selection of the belt material is being selected by BELTCON from certified supplier with High-end quality and environmental conditions.

- Frame: The frame provides structural support for the conveyor and holds the rollers or pulleys in place. It is typically made of steel or aluminium to ensure durability and stability.

- Rollers or Pulleys: Rollers or pulleys are used to support and guide the conveyor belt. They can be powered or non-powered, depending on the conveyor’s design. Powered rollers are connected to a motor to drive the belt, while non-powered rollers provide support and tension to keep the belt in place.

- Drive System: In powered belt conveyors, the drive system includes an electric motor, gearbox, and drive pulley that move the conveyor belt. The motor’s power and speed are chosen based on the conveyor’s capacity and the materials being transported.

- Loading and Unloading Points: These are the entry and exit points where materials are placed onto or removed from the conveyor. Loading and unloading mechanisms can vary depending on the specific application, and they may include chutes, hoppers, or automated systems.

- Supports and Stands: These are used to elevate the conveyor to the desired height, ensuring proper alignment and clearance for the materials being transported. Supports and stands are typically adjustable to accommodate different area configurations.

- Safety Features: Safety features are essential for protecting workers and preventing accidents. These may include emergency stop buttons, guards, and safety interlock systems that shut down the conveyor in case of an emergency.

- Controls and Automation: Conveyors can be integrated into larger automated systems and controlled through programmable logic controllers (PLCs) or computer-based control systems. Automation allows for precise control over the conveyor’s speed, direction, and Baggage handling processes.

- Belt Tracking and Tensioning Mechanisms: To ensure the belt stays centered and properly tensioned, tracking and tensioning mechanisms are often included in the conveyor design.

- Maintenance and Inspection Points: These are designed to allow easy access for maintenance tasks such as belt replacement, cleaning, and routine inspections.

The Following are the standard airport conveyor products include:

- Straight Conveyors

- Collector Conveyors

- Dispatcher Conveyors

- Inclined/Declined Conveyor

- Diverter Arm Conveyor

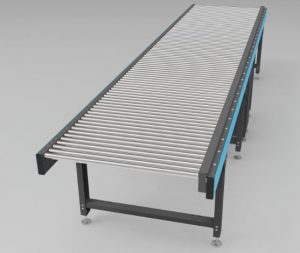

Straight Conveyor

A straight conveyor, also known as a straight-line conveyor or straight belt conveyor, is a fundamental type of material handling equipment used to move goods or materials from one point to another in a straight, linear path. These conveyors are widely employed in various industries, including manufacturing, distribution, warehousing, and logistics.

BELTCON offers standard and customized conveyor solutions to satisfy the material handling requirements for various industries.

Collector Conveyor

A collector conveyor, often referred to as a collecting conveyor, is a specialized type of conveyor system used in material handling and manufacturing environments. Its primary function is to collect and accumulate items or materials from various sources and transport them to a central location or downstream processing point. Collector conveyors play a crucial role in streamlining production and distribution processes. It is the type of conveyor that collects all the check in counter that being dispatch from dispatch conveyor.

BELTCON offers standard and customized conveyor solutions to satisfy the material handling requirements for various industries.

Dispatch Conveyor

A dispatcher conveyor is a specialized type of conveyor system used in Baggage handling System to dispatch the baggage from check in counter, it is usually followed from weighing conveyor. Its primary function is to dispatch baggage to collector conveyor. Dispatcher conveyors play a crucial role in dispatching processes

Inclined/Declined Conveyor

An inclined/Declined conveyor, often referred to as a conveyor incline, is a type of material handling equipment used to transport goods or materials from one level to another at an incline or slope. Inclined conveyors are designed to move items up or down an inclined surface, allowing for efficient elevation changes in a variety of industrial applications.

Diverter Arm Conveyor

A specialized type of conveyor system used in material handling and logistics applications. Its primary purpose is to sort or divert items or products from one conveyor line to another based on predetermined criteria. This type of conveyor is commonly used in distribution centers, warehouses, airports to streamline the flow of materials or products.