Global Friction Tester Equipment - GFTE

| Company | Scandinavian Airfield Systems AB (SAS-AB) |

|---|---|

| Product code | GFTE |

Images

The Global Friction Tester Equipment (GFTE) meets all the airport requirements for measuring the RWY surface friction condition. The FAA approved GFTE, is one top of the line high quality fixed slip Continuous Friction Measurement Equipment (CFME), operating in accordance with recommendations and regulations stipulated by ICAO and the FAA. The GFTE surface friction tester is designed for both operational and for maintenance purposes, using the operational test tire UNITESTER T520 or the maintenance test tire ASTM E 1551. With the ICAO Global Reporting Format (GRF) recommendations, the GFTE helps the operator to evaluate and to report accurate and correct data on time.

The GFTE can be built into a various selection of vehicles, fully integrated within the car chassis. The GFTE is also available as a tow behind model, one fully self-contained surface friction tester trailer.

Global Friction Tester Equipment – GFTE

* Surface Friction Tester – SFT, approved by the FAA and the CAAC.

* EC Declaration of conformity. Machinery Directive 2006/42/EC.

* The measurement wheel has a standardized measuring tire, as stipulated by ICAO and the FAA.

* Fixed slip ratio chain transmission with a stainless acid proof case to stand the chemicals used on the airfield.

* Hydraulic system for controlling the down force on the measurement wheel.

* Electronic sensors for accurate calculation of the friction data.

* FTMS measuring and presentation program, running on a user-friendly and ergonomically installed tablet.

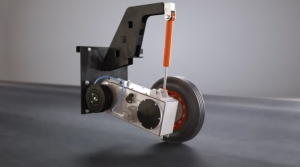

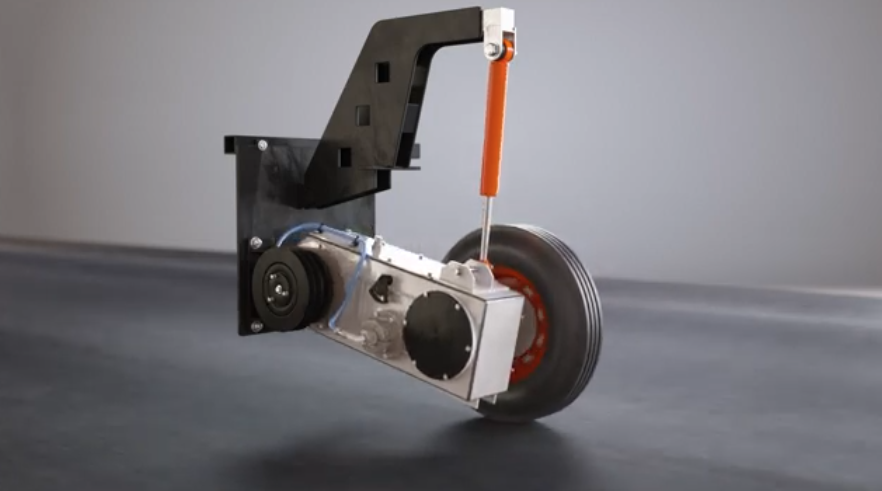

* Water system – for maintenance measurements.

The GFTE, is basically a system for measuring the friction between the GFTE’s measurement wheel and the surface of the ground. The main components are: Measurement wheel with a raising and lowering mechanism, a single chain transmission, a drive shaft between the reference wheel and the chain transmission and a measurement computer system.

Fixed slip ratio chain transmission

The chain transmission is fully integrated in the transmission arm (the case is made of Stainless steel) and the measuring wheel is braked by the reference wheel. The slip ratio is approximately 12% and the skidding gives rise to a moment (force) in the chain transmission, which is read via the horizontal load sensor.

Hydraulic system

The raising and the lowering mechanism of the measurement wheel is controlled by the hydraulic system. The hydraulic system consists of electrically driven pump, cylinder, pressure switches and directional valves.

Electronic sensors for accurate calculation of the friction data – FTMS program

The down force on the measurement wheel is controlled by the hydraulic system. One vertical load sensor is used for active control of the hydraulic down force.

The two measured values, horizontal and vertical, are sent to the computer via one A/D converter and the FTMS program presents the data accordingly.

Water system

The GFTE units can be equipped with a 500/650 litres water tank as an integral part of the GFTE water system. The water flow is controlled by one electrically driven mechanical pump and one electrical valve to supply the correct water film via a nozzle in front of the measuring wheel.

Selection of base cars for built in GFTEs:

Peugeot eEXPERT – 100% fully electric car

Peugeot 5008 – Diesel or gasoline engines

Citroen C5 Aircross – Diesel or gasoline engines

Self-contained GFTE trailer:

Base trailer: Professional trailer – Fogelsta L1251B