Inflatable Industrial Workshops

| Company | ANGARSTROY COMPANY |

|---|

Images

Inflatable hangars used as production buildings of plants and factories, welding and industrial workshops are a single mobile solution for providing support, repair, assembly of equipment and production of products at the place of operation. This type of design is ideal for the rapid construction of a workshop in challenging climatic conditions.

Design solution

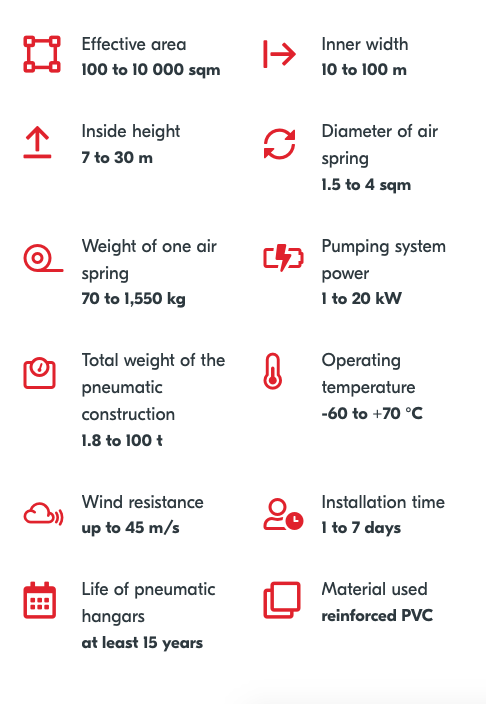

An inflatable hangar is an inflatable structure made of reinforced PVC materials, consisting of forming pneumatic cylinders, end walls with doorways of inflatable gates, connected in a single structure and covered with a prefabricated shell.

Each inflatable cylinder is a half-torus design, which is automatically filled with air using an intelligent booster system. The end walls are equipped with door blocks, inflatable gates, openings for supply and exhaust ventilation and heat-insulated channels for the chimney.

For staff and visitors, aluminum doors with closers on a metal frame are provided. Cargo gates open with an electric hoist, providing pass-through for machinery and equipment.

The pre-fabricated protective shell covers the inflatable cylinders, providing increased wind and snow resistance, and also improves the heat-saving specifications of the structure.

Comfortable working conditions for staff

Thanks to heating, ventilation and air conditioning systems, as well as uniform and bright lighting, our hangars provide comfortable, if not to say luxurious, working conditions for staff. Creating the most favorable conditions for employees affects the quality and speed of work processes.

Improved quality of maintenance

Due to the ever-increasing demand for saving resources and the high cost of equipment, the majority of mining companies takes the control of indoor air cleanliness very seriously in order to reduce the amount of foreign materials introduced into the equipment through liquids and perform all maintenance and repair operations.

Suitable for hosting equipment of any size

Thanks to the universal modular structure, our hangars are able to host the largest models of dump trucks, excavators and other types of equipment. Inflatable structures can have a traditional layout with one entrance gate, as well as a layout with two gates to provide a through passage.

Reduced downtime and idle runs

There’s no more need to move your excavators, dump trucks and drilling rigs to remote repair facilities for maintenance and repairs. Instead, put your repair shop where the work is done. Thus, you will reduce downtime, idle runs, deferred repairs and maintenance, thereby increasing the life of your equipment.

Increased mobilization speed

Your hangar can be dismantled and installed in a new place just in a few days, which makes it possible to use the workshop to carry out maintenance at all your facilities where necessary. The compact packaging and low weight of the product reduce transportation costs, when installing the hangar does not require a large construction team, special equipment and lifting mechanisms.

Indispensable when working in hard-to-reach areas

Our mobile hangars work in locations where no other alternatives exist. Thanks to the compact packaging and low weight of the structure, our customers can deliver structures to the most remote and inaccessible places. Inflatable hangars can be installed in seismically active areas. Thanks to the inflatable structure and the absence of rigid elements and the foundation, the hangars do not take any damage even with the most severe earthquakes.