AFC Cooling System Saves Time And Money

| Company | FCS Finland Ltd |

|---|---|

| Date | 26.05.2023 |

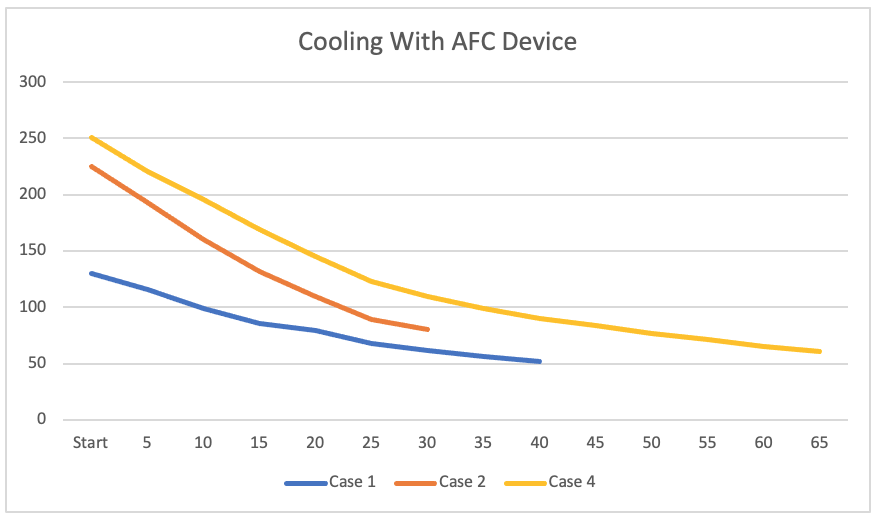

By using AFC Cooling Device maintenance/ inspections on core and accessories can be conducted safely in 60 minutes.

The proven technology uses a vacuum to pull heat out from engine´s exhaust pipe to cool down the core and case. Ambient air flows through the engine´s flow path. This shortens the cooling time required which enables borescope inspection to be started earlier.

LESS DOWNTIME

The AFC-22 and AFC-23 cut the cooling down time of an aircraft engine to it’s fraction. Our customers can make huge cost savings and optimize their fleet with the AFC-22 and AFC-23 cooling as a standard maintenance process.

Compared to dry motoring our system saves the valuable Air Starter Unit, because no engine cranking is required to cool down the engine. Dry motoring is very stressful procedure for the start motor increasing its need for maintenance, and the cooling effect itself is weak. After dry motoring, you still have to wait about 3-3,5 hours, depending, for example, the type of engine and weather conditions, before starting the maintenance procedure.

With FCS Cooling System hot section maintenance (e.g., borescope inspections) can be started in 40 min, when cooling started. With passive cooling it would take about 4-5 hours, this has been verified by several airlines and the time saving ratio is roughly 1:4

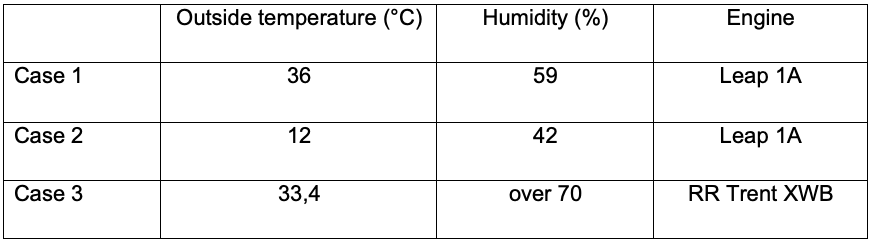

DEMONSTRATION WITH RR TRENT XWB ENGINE

Testing conditions:

- AFC-22 Cooling System

- Outside air temp 33,4 °C

- Humidity over 70%

- Airbus 350-900 Passenger Aircraft

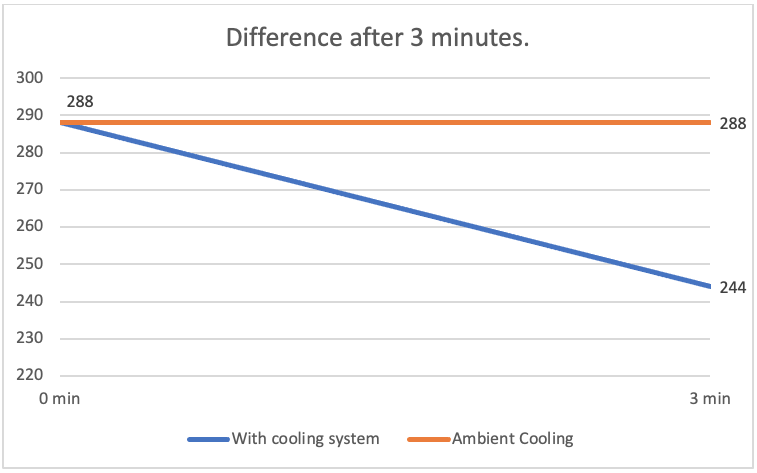

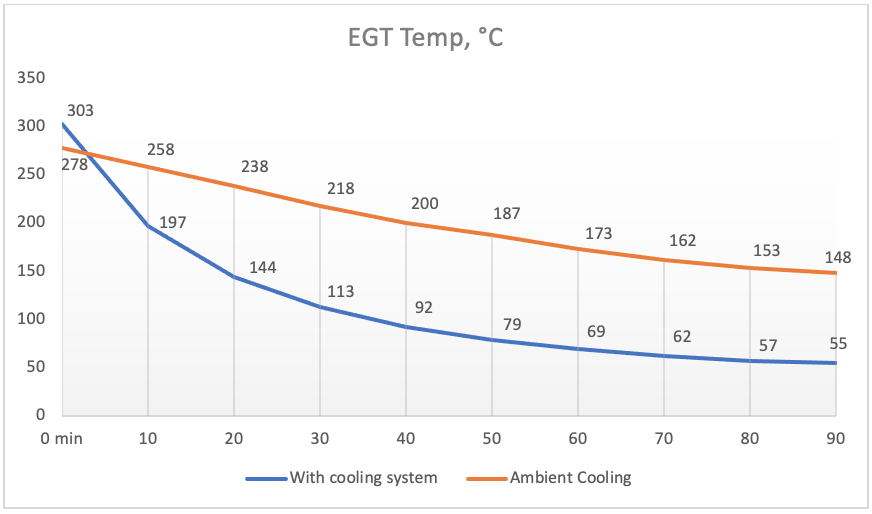

After 3 minutes, the disparity between the AFC-22 cooled engine and the ambient cooled engines EGT was (244 °C vs. 288°C), a 40°C delta.

After 1 hour, the disparity between the AFC-22 cooled engine and the ambient cooled engines EGT was (72°C vs. 211°C), a 140°C delta.

The test temperature of 60°C was reached after an hour and 15 minutes with AFC-22 cooling system.

The engine with ambient cooling reached 60°C in 6 hours and 4 minutes.

DEMONSTRATION OBSERVATIONS; PROS

+ Equipment was very easy to move/store/setup/takedown

+ It took ~2 minutes to install and start cooling

+ No supervision of equipment is required. AMTs can start the cart and leave to work on other tasks

+ Cart was quieter than expected when at full power

+ Adapter fits perfectly on the engine – did not notice any sort of sealing issue leakage

+ Cowls can be open or close while adapter is in place

+ No servicing required to upkeep equipment

ENGINE COOLING WITH OUR SYSTEM:

- Optimizes your fleet

- Minimizes Out of Service or BSI planned event downtime

- Achieves significant operational time and cost savings

- Carbon footprint reduction