Kee Safety - BEAMCLAMP and BOXBOLT - Secure fixings for secondary steel connections

| Company | Kee Safety Limited |

|---|---|

| Date | 02.06.2015 |

John Kay, UK Sales Manager at Kee Safety, a leading global supplier of steel to steel connectors, discusses the features and benefits of its leading product ranges, BEAMCLAMP and BOXBOLT in the latest Fastener & Fixing Magazine issue, on page 92.

Since its launch in 2005, the extensive range of BEAMCLAMP and BOXBOLT solutions from Kee Safety has gone from strength to strength, with growth all across the world. The BEAMCLAMP and BOXBOLT range of fixings from Kee Safety is a series of products that provide a secure fixing method for secondary steel connections. The fixings deliver solutions for joining steel together without the need for on-site drilling or welding, providing much more flexibility than traditional methods. The system provides a guaranteed connection every time, without the need for on-site verification, as long as the installation guidelines are correctly followed.

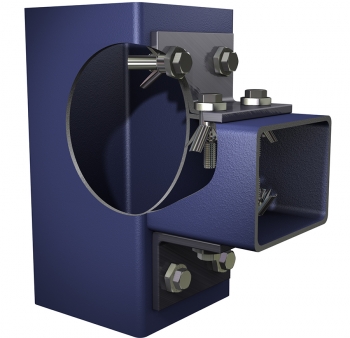

BoxBolt®

The BOXBOLT range is the blind fixing solution for connecting into hollow sections, or where access is restricted to one side only. This system provides an economical solution to making blind connections, when compared with traditional methods such as welding or bolting through. The system eliminates complicated fabrications such as welding internal nuts or providing internal stiffeners to reduce crushing from tightening.

| FEATURES | BENEFITS |

| No access to both sides of the connection required | No through bolting or strapping required reducing fabrication work |

| No need for close tolerance holes or tapping | Flexibility and reduced on-site installation time |

| No special tools required – two spanners only | Reduction in installation cost and administration |

| Installation by semi-skilled labour | Reduction in labour and hire costs |

| Only BoxBolt head visible when installed | Flexibility in architectural design |

| Approved for use by Lloyds Register Type and DIBt | Confidence that the connection will perform as stated without site proof testing required |

| Exceptional shear loading performance | Flexibility in design and possible cost reductions |

| AISC and Eurocode 3 Method for designing connections | Designers easily recognised the method and can save costs on competitive methods |

| BOXSOK rapid installation tool | Reduction in on-site labour costs |

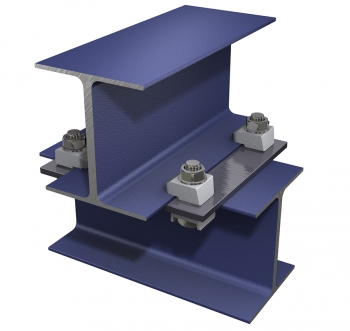

BeamClamp®

The BEAMCLAMP range is a series of clamps that are used in conjunction with structural bolts to provide a solution for securing steel together. When all the costs that are required to make a connection are calculated, the clamping system, in the majority of situations, is the most economical, as the installation speed and labour costs are vastly reduced. There are many other benefits such as a guaranteed load, adjustability, no damage to existing steel or coatings, no hot work permits and no debris created from drilling. These benefits are becoming very important in situations where drilling and welding can create hazards. For example, in a food factory, no drilling is permitted over the plant and in an oil refinery, a hot work permit is required for making any drilled or welded connections.

| FEATURES | BENEFITS |

| Third party approvals (Lloyds & DIBt) | Peace of mind when specifying or installing |

| Guaranteed 5 to 1 factor of safety | Provides safe connections |

| No special tools or skilled labour required | Savings in installation time and cost on-site |

| Hot dip galvanised as standard | Excellent long term corrosion resistance for external applications |

| Easy to adjust on site | Provides flexibility to allow for site tolerances |

| No weakening of existing steelwork | Structural integrity of steelwork remains unchanged |

| No damage to protective coating on the steelwork | Integrity of existing steelwork coating remains unchanged |

BeamClamp® Floor Fixings

The Floor fixings range is hot dip galvanised to provide excellent corrosion resistance. Using these fixings allows for site tolerances and the ability to relocate the connection should it be required. The range consists of FLORFIX, FLORFIX HT, GRATING CLIP and GRATEFIX.

FLORFIX HT provides a fixing which suits a wide range of applications. It was designed to fix flooring plates to supporting steelwork from the topside only, without the need for time consuming on site drilling, tapping, bolting or welding. It works on a cam mechanism that can be operated using a basic hexagon key drive.

This type of system allows steel erectors a high degree of tolerance. It retains all the benefits of Kee Safety’s widely renowned original design, but is far more user friendly. FLORFIX HT allows for floor plates to be fixed to new steelwork that is erected within +/- 6mm of its intended position. It is capable of fixing to steel flanges from 3 to 25mm without the need for additional packing pieces.

| FEATURES |

| Allows for +/- 6mm construction tolerance |

| Can fix up to 25mm thick steel as standard |

| Hot Dip Galvanised finish as standard |

| Easily installed from the top side only |

| No drilling, no tapping or welding required |

| Allows easy repositioning or lifting of floor plate |

| No special tools or skilled labour required |

| No access to the underside required |

| Tested for vibration conditions at TÜV |

More information about Kee Safety fixings for secondary steel connections is available on our BeamClamp website.

Contact

Cradley Business Park

Overend Road

Cradley Heath

United Kingdom

B64 7DW

- +44 (0 )1384 632 398