Doosan Rushlift Fleet Management System - Access to real-time fleet information on a 24/7 basis.

| Company | Rushlift GSE |

|---|---|

| Date | 04.05.2016 |

Doosan’s wholly owned subsidiary Rushlift, is launching a new Fleet Management System (FMS). Originally developed in 2005, the latest revision of the website allows all customers access to real-time fleet information on a 24/7 basis. This ensures customers are optimising their materials handling equipment.

Through Doosan Rushlift’s IT team at the Northampton premises, the FMS website has been developed in-house allowing us to maintain and update as and when required, ensuring that customers are always kept up-to-date with the latest FMS functionality and website enhancments.

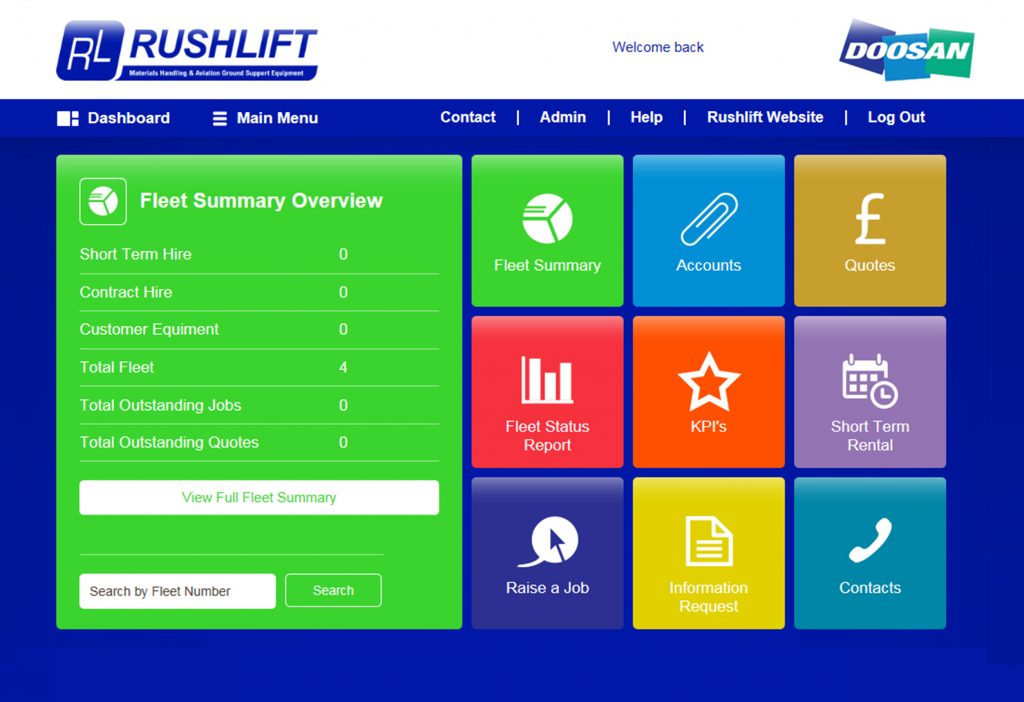

Each customer is provided with their own login details, enabling them to have complete visibility of their equipment and its history; this new online system allows customers to log breakdowns on a 24/7 basis, monitor uptime and fleet utilisation, request and authorise quotes for repairs, as well as review accounts information. The major benefit here is that these improvements to the FMS website enables the customer to make informed decisions based on real time information.

With the ability to log breakdowns and repairs online, there is no longer the need to make a phone call to report a problem. Once a job is registered online, the job is issued by the operations team to a Doosan Rushlift engineer, who will then action and arrange to resolve the problem.

The ‘Fleet Summary’ section allows the customer to monitor progress of any breakdowns or repairs, providing a live indication of the estimated time of arrival of the engineer as well as an update on the status of the job. This is also updated to the customers via email, if required.

Live information is fed into the FMS website from the engineer’s tablet whenever they visit site with all maintenance records being updated in real time. The Doosan Rushlift system provides important data on customer’s equipment, including uptime, utilisation and other Key Performance Indicators (KPI’s).

The FMS provides more control to a business, the customer can access the ‘Fleet Status’ page of the website at any point and see an overview of their whole fleet. Replacement trucks can also be requested through the online system – an added benefit, to minimise downtime even further.

Tim Waples, CEO of Doosan Industrial Vehicle UK, explains “over the last 10 years, the Doosan Rushlift IT team have developed our own, in-house, comprehensive web-based Fleet Management System (FMS). This industry-leading solution enables customers to access up-to-date information on its equipment fleet, log breakdowns on a 24/7 basis and to access maintenance records, account details and other important information.”

This system is free of charge, all part of the service.

Contact

Building 16300

Elmdon Road

Heathrow Airport

Hounslow

Middlesex

United Kingdom

TW6 2DN

- 020 8564 4949