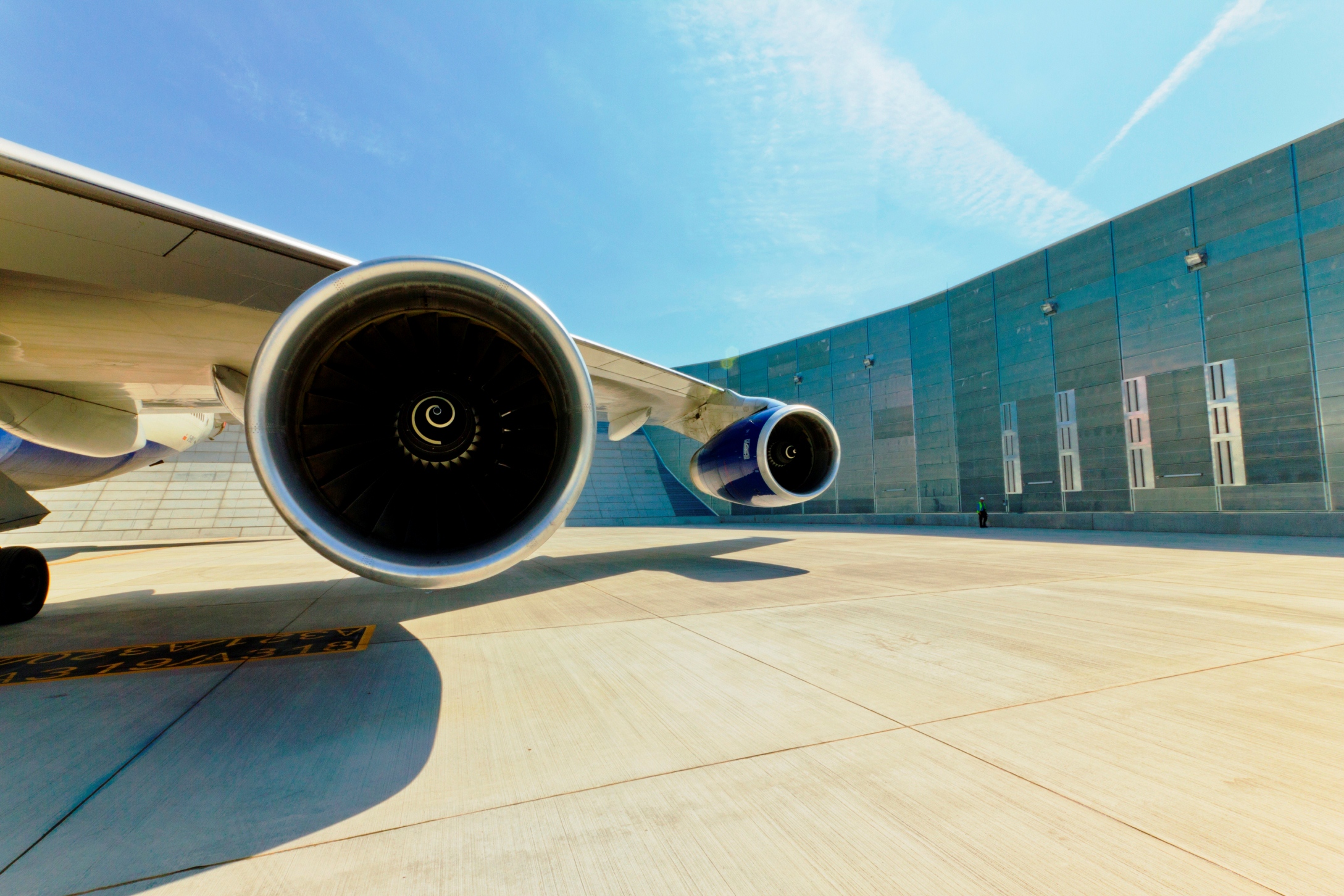

IAC Acoustics has announced the handover of two new Ground Run Enclosures (GREs) to British Airways at London Heathrow Airport. A wealth of experience in outdoor on-wing engine testing, combined with the latest simulation techniques, was used to achieve the most significant steps forward in GRE equipment in over a decade.

IAC Acoustics has announced the handover of two new Ground Run Enclosures (GREs) to British Airways at London Heathrow Airport. A wealth of experience in outdoor on-wing engine testing, combined with the latest simulation techniques, was used to achieve the most significant steps forward in GRE equipment in over a decade.

IAC worked closely with British Airways and the London Borough of Hillingdon to determine the location and site requirements for the new GREs, in order to minimise noise to neighbouring communities. Benefiting from modular assembly, the project was delivered to a tight schedule around other works for the BA A380 Maintenance Project.

Two new A380-sized GREs were delivered to British Airways at Heathrow airport, with IAC focusing on maximising the operational availability of these facilities through superior aerodynamic and acoustic performance. The next generation of GREs will accommodate up to A380 aircraft for post-maintenance engine testing, including take off power, and are constructed using (patent pending) sections Jetshield™ (rear wall) and Aerowall™ (side walls).

Fraser Alexander, Chief Engineer at IAC Global Aviation said: “The focus for development of our existing products has been the need for increased utilisation, irrespective of wind direction and the need to fit what can be large pieces of equipment into the existing infrastructure at sometimes crowded airports. Our aim was to develop a GRE that is modular, scaleable, easy to manufacture, ship and install – maximising benefits to the customer beyond just improving performance. In meeting our goals, the new range of GRE products has been an exciting challenge for the aero-acoustic team”.

Fraser Alexander, Chief Engineer at IAC Global Aviation said: “The focus for development of our existing products has been the need for increased utilisation, irrespective of wind direction and the need to fit what can be large pieces of equipment into the existing infrastructure at sometimes crowded airports. Our aim was to develop a GRE that is modular, scaleable, easy to manufacture, ship and install – maximising benefits to the customer beyond just improving performance. In meeting our goals, the new range of GRE products has been an exciting challenge for the aero-acoustic team”.

Duncan Hislop, British Airways Property Development Manager at Heathrow, said: " British Airways is committed to reducing the impact of noise levels on neighbouring communities as far as possible, and saw IAC as the right candidate to achieve this"

Historically, the science of improving the acoustics of a GRE has tended to compromise aerodynamic performance. For pure jet applications, this is often an acceptable compromise. However, the arrival of the ultra high by-pass turbofan has demanded better aerodynamic performance to complement the acoustics. IAC has used a combination of thorough product research and cutting-edge modeling and measurement tools to develop a more advanced product than previously available.

IAC’s new GREs offer an improved aerodynamic configuration to maximise the conditions under which testing can take place from the smallest to the largest of today’s aircraft. The acoustic performance is also maximised by the use of a combination of field-proven IAC products and builds upon IAC’s reputation in world leading noise control solutions.

The next generation GRE reduces the effect of engine noise, vortices and re-ingestion – which might otherwise cause engines to stall. The Jetshield™ rear wall delivers a unique aerodynamic and acoustic performance in a single structure, reducing the overall footprint of the facility. The Aerowall™ side walls, are specifically designed to offer aerodynamic and acoustic performance. Finally, by incorporating IAC Powerflow™ silencers, the walls mitigate the detrimental effects of crosswinds, while reducing airflow distortion and vortices within the facility. These improvements result in a GRE which can be used more often, in conditions that were not previously possible.