How could the supply chain at the airports be optimised?

| Company | Moveco Systems S.r.l. |

|---|---|

| Date | 03.04.2023 |

The last few years have been a real revolution for the world of logistics.

The large increase in demand due to the pandemic has been dampened by a global increase in costs due to the consequent shortage of raw materials, which is also due to the war between Russia and Ukraine, and a drop in manpower due to an aging population which does not it has been renewed by the new generations, who are more reluctant to approach manual labor.

This is why process efficiency is essential for business continuity and profitability, especially in these unpredictable times.

Automation is a great ally in this sense, because in addition to offering significant savings on management costs and personnel, it also offers greater security within the entire company structure, as well as a significant reduction in errors that are humanly committed at the workplace.

Is it possible to automate everything? What can airport warehouses do?

Although airport warehouses are subject to very strict regulations, due to the need to handle load units which have different characteristics compared to those used in intermodal transport, and which are more binding from an automation point of view, there are nonetheless efficiency solutions.

Within the airport warehouse, supply chain managers should often consider individual logistics processes and their impact on the overall efficiency of the business. For example, wondering if such a process could and should be automated, and how much the company could save with automation.

The setup of the vehicles used to transport goods between the factories and the airport warehouse, for example, has a very high impact on efficiency and safety, and significantly increases the quality of work.

The design of the airport warehouse is therefore a crucial phase to guarantee the efficiency in the management of the load units that have to be loaded or unloaded from the planes.

For this reason it is advisable to rely on a team of experts who know how to respond to your needs and know how to consider any problems associated with each project in advance, evaluating possible solutions to ensure maximum efficiency.

Data analysis

All the best optimization solutions start from data analysis.

Measuring your logistics processes is an activity that allows you to have a fundamental starting point for defining any growth strategy. This approach is also valid when it comes to defining an airport warehouse.

Having clear ideas about the type and quantity of pallets that will pass through the warehouse on a daily basis allows you to correctly size the necessary spaces and provide for the right amount of inputs and outputs. It is absolutely normal and necessary to provide the manufacturer with all the information useful for designing the best solution.

A modular solution

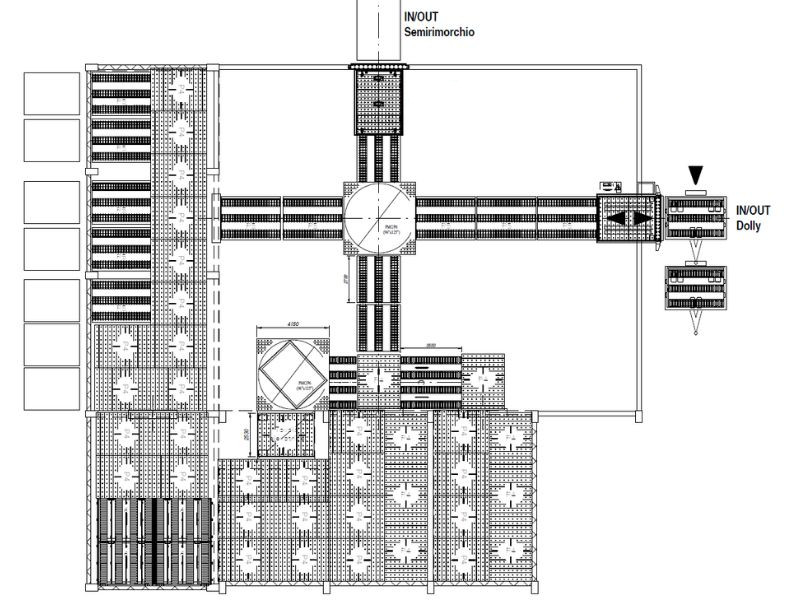

Modern plants are generally designed starting from a module sized according to the types of pallets and containers in transit, which is adapted to each warehouse in order to offer all the handling and management possibilities required.

This makes it possible to significantly reduce production costs and at the same time offer broad compatibility between the different load units used.

There are several modular solutions, starting from basic handling modules such as ball, roller or castor deck tables, up to lifting or weighing platforms, in order to obtain complete management, whether it is a simple transfer of load units from dolly to semi-trailer and conversely, or whether it is a storage and preparation need. vice versa

For the handling of heavier loads it is also possible to install some powered rollers. This more advanced solution allows you to move the pallets automatically, without the manual intervention of the operator.

Without this type of system it would be very difficult to manage a warehouse for air pallets and ULDs.

Offer an intermodal transport

How is the goods transported from a company site to an airport?

The main difficulty of transport that takes place by air is that the goods must be transported on dedicated pallets and containers, which are incompatible with the rest of the logistics chain.

This need is obviously due to travel conditions. The hold in the fuselage of an aircraft requires maximum optimization of the spaces occupied and at the same time it is essential not to add weight to the load.

Air pallets and ULD containers are transported to and from the company sites using semi-trailers, equipped with roller conveyors to facilitate its handling.

For supply chain managers, this is an opportunity to take logistics efficiency to the next level.

Having a roller conveyor platform installed on the trailer optimizes and speeds up the handling procedures of any sort cargo units such as ULD or air cargo pallet. That is because the roller conveyor easily interfaces with the warehouse loading bay at the airport, but it can also load standard pallets and withstand the weight of a forklift moving on top of it.

It uses pneumatic supply to upper the rolls so to easily move the goods back ad forward, once the load is completed the rolls lower and all the pallets are well grounded and safe on the conveyor floor.

Do you need to optimize your supply chain?

Optimization requests for supply chains are increasing and constantly evolving. The airport warehouse is an increasingly important piece in the logistics sector and it is vital that the movement of goods remains a continuous flow, without a hitch. If you are looking for an optimization solution for your company, or if you manage an airport warehouse and want to offer your customers the best service, do not hesitate to contact Moveco Systems. We will find the best solution for your company.

Contact

Via Arturo Biella, 1

28075 - Grignasco (NO)

Italy

- +39 0163 418 939