GRF regulations demands knowledge on aircraft performance. Contaminant selection and RWYCC assessment is based upon trained person’s judgement considering the effect on airplane performance. In this context the trained person refers to runway inspector responsible for runway condition reporting.

Are you familiar with aircraft performance?

What is the difference of takeoff- and landing performance? Should runway inspector selection in RCAM table be based upon takeoff- or landing critical contaminant? Are these two choices contradictory?

Short lesson on take-off and landing performance:

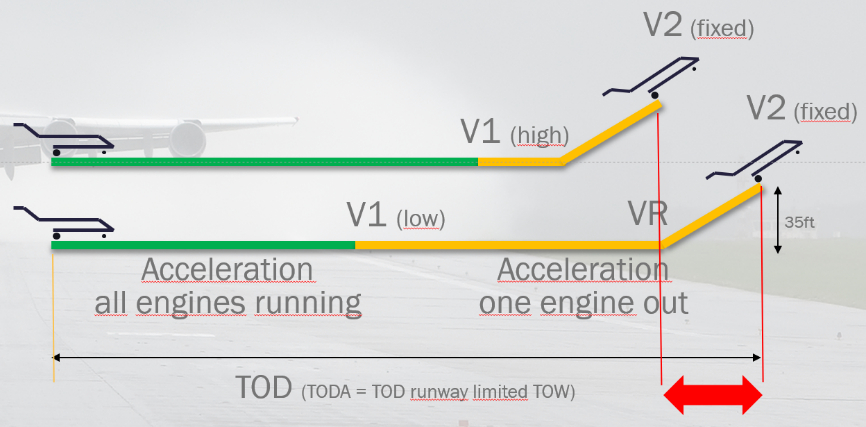

In terms of aircraft performance takeoff and landing are two totally different events. In takeoff, two scenarios must be considered: continued takeoff and aborted takeoff. In continued takeoff, contaminant drag must be taken into account. Contaminant drag plays utmost important role and may have significant effect on aircraft acceleration and thus required runway length.

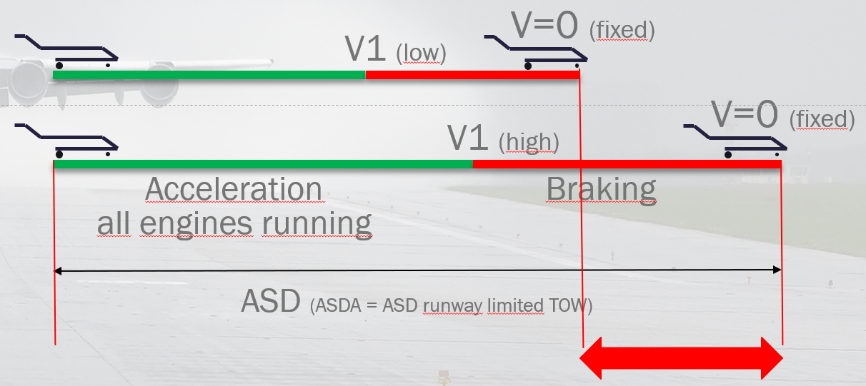

In aborted takeoff, low friction impacts aircraft performance by lowering aircraft’s stopping capability. Therefore, all “basic” contaminant types have inbuilt regulatory friction coefficients. Aircraft manufacturers use these friction values when calculating aircraft behavior in aborted takeoff. RWYCC-value is not used as a parameter in aborted takeoff calculation.

Note: Takeoff performance calculation is solely based upon contaminant type and depth. Takeoff performance has nothing to do with reported runway condition code RWYCC-value.

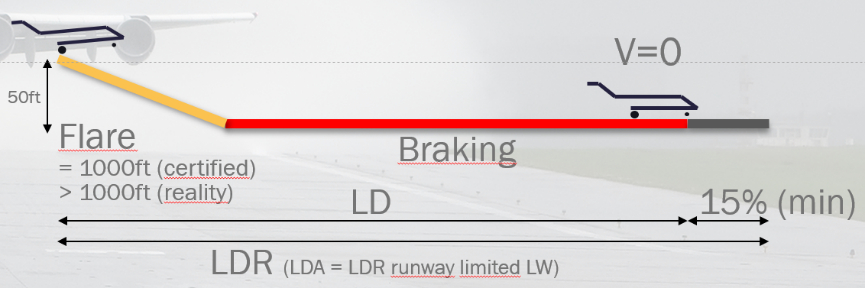

In landing contaminant drag is considered credit, which is not taken into account. In flight planning phase landing performance calculation is based on contaminant type and depth. When airborne, pilots are calculating landing performance shortly after top of descent. This so called “in flight” calculation. “In flight” calculation can be based solely on RWYCC-value.

Note: One step too high RWYCC-value report may “eat” the 15% margin.

Conclusion regarding aircraft performance and RCAM table assessment:

RCAM table was originally designed to support runway condition assessment from landing performance point of view. That is why RWYCC-value plays major role in the assessment. However, RWYCC-value has no role in takeoff performance. To safely cover both takeoff and landing, runway inspector should choose RCAM contaminant having greatest impact on takeoff performance and RWYCC-value having correct effect on landing performance.

Note: runway condition report (RCR), SNOWTAM and ATIS should serve both takeoff and landing.

To safely cover takeoff and landing, in certain runway conditions may require reporting, where RCAM contaminant type and its respective (nominal) RWYCC-value cannot be “locked” and a RWYCC downgrade procedure should be applied.

Global Runway Reporter application (GRR), aircraft performance and RCAM:

To safely implement GRF reporting and RCAM assessment requires profound understanding of aircraft performance in respect to both takeoff and landing. Global Runway Reporter (GRR) application has inbuilt “knowledge” about aircraft performance and GRR offers great relief for the runway inspector in respect to aircraft performance consideration during runway condition observation, RCAM assessment and reporting. When using GRR, runway inspector can focus on the essential: observing the seven “good old familiar” contaminants. Based on runway inspector’s input, GRR will take care of takeoff critical RCAM contaminant generation and landing critical RWYCC-value tracking. Best possible real time guidance is given to the inspector to carry out safe runway condition code assessment.

If not already done, check here if you have done all the necessary preparations for GRF. If you wish to have more information about our Global Runway Reporter (GRR) application feel free to contact us.