Latest News from Pollite - November 2016 Newsletter

| Company | Pollite |

|---|---|

| Date | 18.11.2016 |

NOVEMBER 2016 NEWSLETTER.

In this issue we update you on the latest industry news, update non-compliant concrete structures in Bulgaria and announce a new relationship.

POLLITE AND LILY HELIPADS TAKE OFF TOGETHER

All Pollite Windsock masts are manufactured from glassfibre and polyester resin, finished with a UV resistant gel coat. Each pole has a unique break system incorporated within the main mast and is coloured to client specifications. The windsock cone is manufactured from 316 marine grade stainless steel and both external and internal lighting is available. All windsocks are manufactured from a durable polyester which is available hypalon coated if required and UV tested to ensure a longer vibrancy of colour.

Pollite are proud to announce our new partnership with Lily Helipads LLC based in Indianapolis, USA. Click here to view their website.

The deal will see Pollite internally lit windsocks and frangible fibreglass masts installed on Lily Helipads safe, environmentally friendly helipads across the United States.

The helipads custom tailored and combine the latest in helipad construction technology and aeronautical design. They are permeable and able to capture and contain deicing fluid or any potential fuel spills.

All our Airfield and Heliport windsock masts are compliant with CAA’s CAP168 and ICAO’s Annex 14 Vol. 1 Aerodrome Design and Operations requirements. They comply fully with the frangibility requirements stipulated in ICAO’s Aerodrome Design Manual, pt. 6 frangibility and FAA AC 150/5345-27D. For more information on our Windsock masts click here.

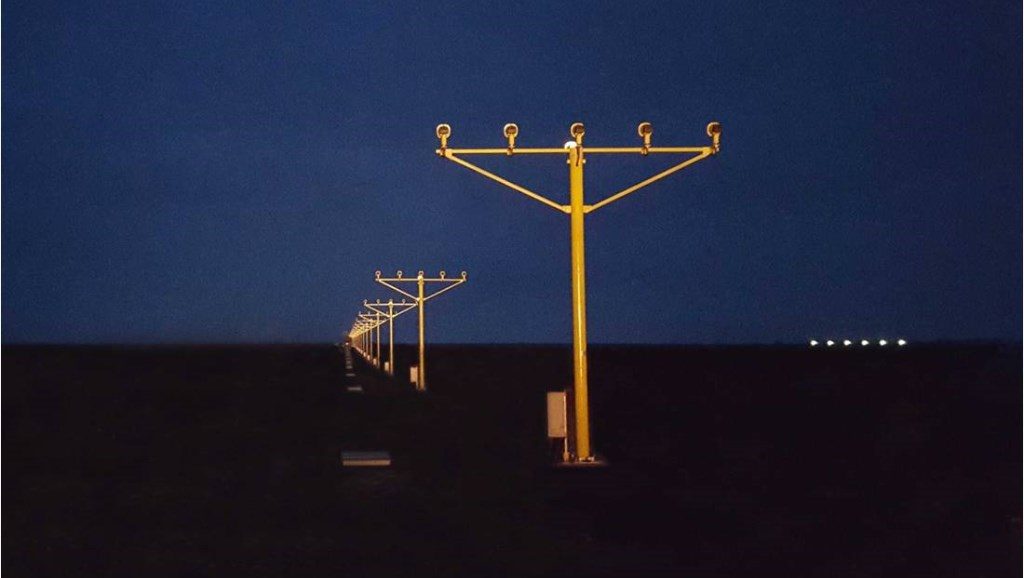

A BESPOKE FRANGIBLE ALTERNATIVE TO NON-COMPLIANT CONCRETE STRUCTURES FOR SUNNY BEACH

Burgas and Varna Airports in Bulgaria, serve the popular holiday resort of Sunny Beach and have recently undergone an upgrade to its airfield ground lighting. Pollite worked together with LOG Siberia to replace their non–compliant ground lighting concrete structures with the latest frangible approach masts.

Due to the unique terrain bespoke designs were needed for each mast. Our team of expert designers developed the masts of up to 16m with mid-hinges for manufacture in our UK facility to the highest safety specifications and ICAO and FAA compliance.

The masts are maintenance and corrosion free and their temperature and weather resistant coating means they can withstand the fluctuating temperatures in Bulgaria, where temperatures range from -10 to 28?C.

Despite the complex project demands we were able to meet the project timescales and dispatch the masts within 6 weeks so they could be installed during the airports off peak season.

INDUSTRY NEWS

Kalstar E195 Final Report

Indonesia’s National Transportation Safety Committee released their final report on the Kalstar E195 accident recently.

The flight with 125 passengers and 5 crew overran the end of the runway while landing in Kupang and came to a stop on soft ground about 200 meters past the end of the runway with the right main gear collapsed.

The passengers were evacuated via slides. Luckily there were no injuries, but the aircraft sustained substantial damage including extensive damage to the right hand wing (flaps, slat, leading edge), minor damage to the nose gear, minor damage to left main gear, damage to all fan blades of the left engine, nicks to the left engine inlet cowl, collapse of the right main gear as result of detached trunnion, right engine cowl contacting ground with inlet cowl receiving nicks, substantial damage to the lower cowl, most fan blades damaged, reverser cowls detached and found 30m from the aircraft, the support beam of the right wing inner rib broken.

The NTSC reported that there was a ground indentation of about 20cm depth about 100 meters past the runway threshold. Up to that point the tracks of the right hand main gear were seen on the ground, thereafter the marks of the right hand engine became visible.

Heathrow to get 3rd Runway

After operating at 98% capacity for over a decade and unable to meet the ever-increasing demand for capacity Heathrow announced its plans to build a 3rd runway last month.

The damage to the right wing was likely caused when the right hand wing felled a palm tree, trunk diameter 40cm, about 185 meters past the runway end highlighting the importance of frangible structures on runway sites.

The report concluded the probable causes of the accident were:

- The steep authority gradient resulted in lack of synergy that contributed to least of alternation to correct the improper condition.

- Improper flight management on approach resulted to the aircraft not fully configured for landing, prolong and high speed on touchdown combined with low brake pressure application resulted in insufficient runway for deceleration.

- The deviation of pilot performance was undetected by the management oversight system.

If approved by MP’s next year work will begin in 2021 and the runway should be open by 2025.

You can see what the proposed expansion will look like in this video:

INTERAIRPORT SOUTH EAST ASIA 2017

We will be exhibiting at Interairport Asia on 15th-17th February 2017. If you would like to set up a meeting during the event email Richard on Richard.landsbury@pollite.com