Safe and Easy Landing Gear Change

| Company | HYDRO Systems KG |

|---|---|

| Date | 04.10.2019 |

The landing gears of the world’s largest commercial aircraft the A380 can support a weight of close to 570 tonnes on take-off and over 390 tonnes on landing. This is why you need to rely 100 percent on its proper function.

Depending on the aircraft model, overhauls typically occur every 8 to 12 years; the exact interval is based on the need to inspect or treat corrosion. A typical landing gear maintenance program can take upwards of 45 days, leaving your airplane out of commission during the overhaul process and making for costly downtime.

Most of today’s landing gear changes are operated with landing gear specific chain hoists. For moving the load hard physical manpower and a team of four to six operators are needed. The lack of repeatable process stability makes it impossible to plan work and staffing efficiently. This existing process is time consuming, not predictable and, therefore, expensive.

What if you could use One Landing Gear Robot for all commercial aircraft?

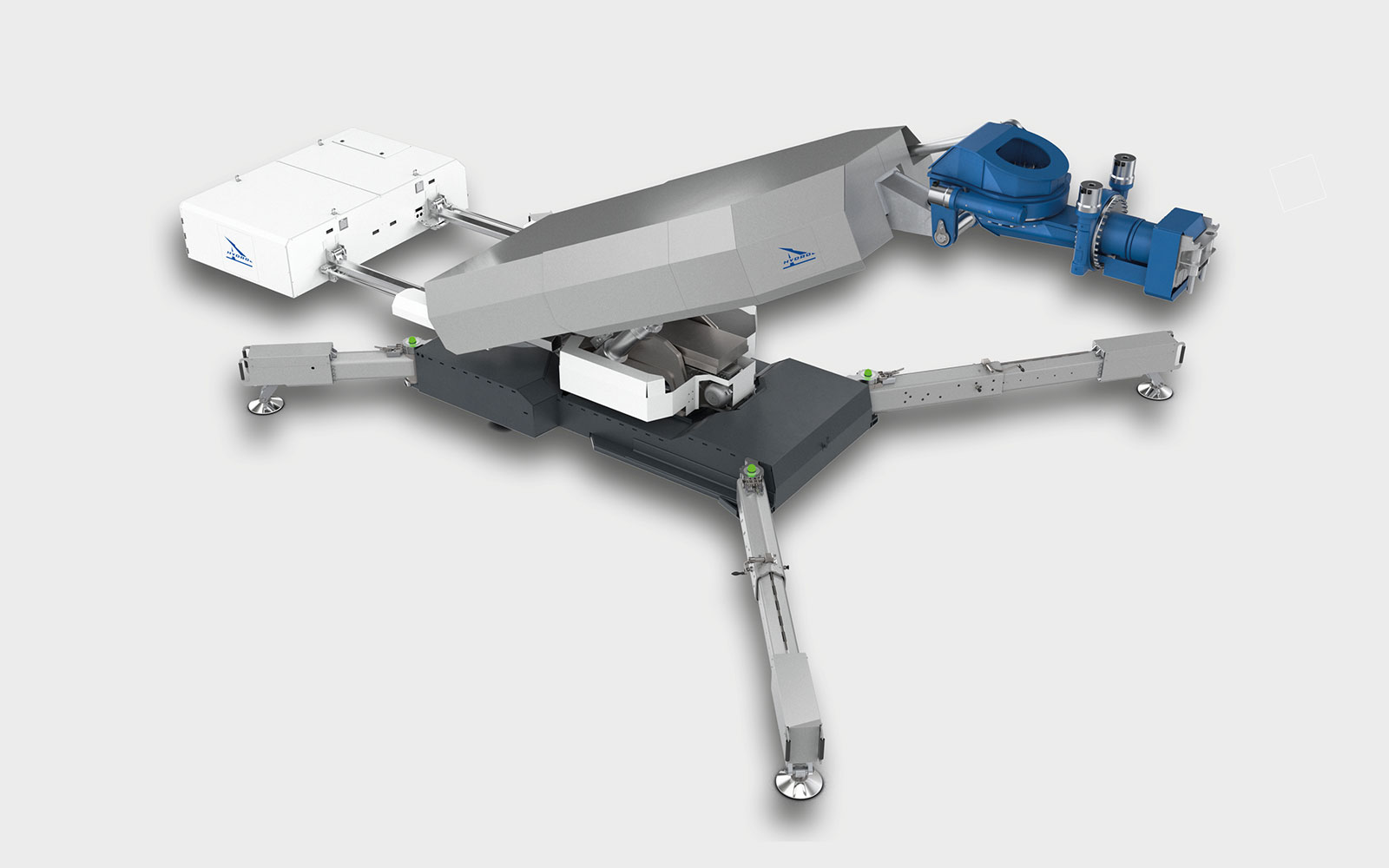

The new electrically powered Landing Gear Robot from HYDRO, with its huge work space and six degrees of freedom (six axes), enables all landing gears of an unprecedented wide range of commercial aircraft to be changed. Its outstanding maneuverability allows precise and easy positioning. The time for exact pre-positioning is over: the huge working space of the LGR compensates for inadequate positioning.

As well as landing gear changes the Landing Gear Robot is suited to a wide variety of other installation applications.

What makes the Landing Gear Robot unparalleled?

The LGR has four hydraulic support struts equipped with electrically lowerable ground plates. All hydraulic cylinders are equipped with magnetostrictive sensors for accurate distance measurement. A special cardan shaft is equipped with electric and hydraulic coupling interfaces. For load balancing a simultaneously extractable counterweight has been implemented, which is also used as the battery container. For safety reasons the load forces are permanently measured and controlled, and the levelling of the LGR works fully automated.

The LGR is powered electrically and can be charged within three hours.

For more information view the Landing Gear Robot brochure here.