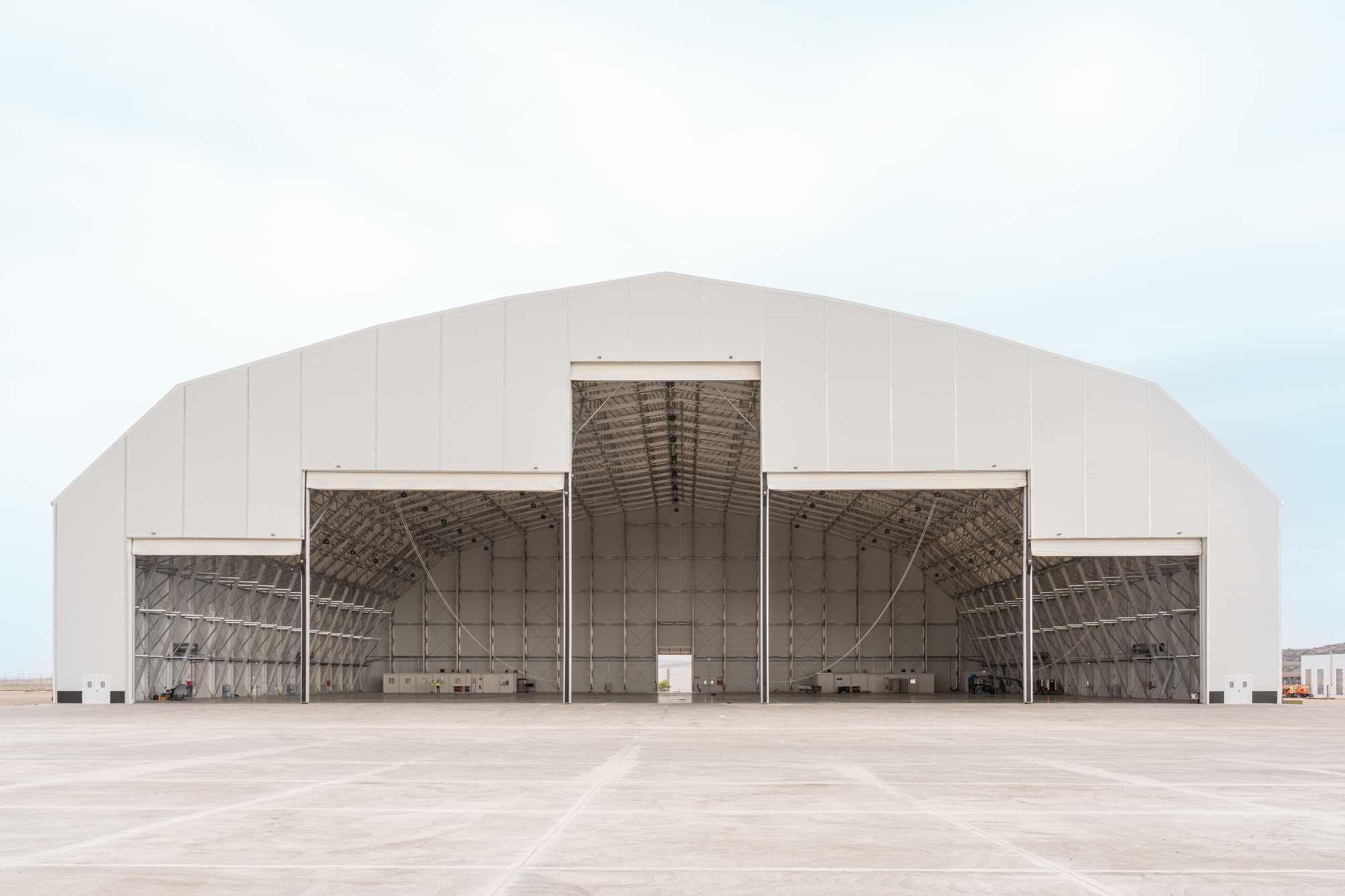

Spantech Completes A380 MRO Hangar for Tarmac Aerosave in Teruel, Spain

| Company | Spantech |

|---|---|

| Date | 19.09.2024 |

In 2023, Spantech was approached by Tarmac Aerosave, a global leader in aircraft storage and maintenance to construct an MRO hangar in the mountainous region of Teruel, Spain. This ambitious project required a facility with a 95-meter free span and a clear height of 29 meters, capable of comfortably housing an Airbus A380.

Project Timeline and Scope

The project started in 2024 at the beginning of February and was completed by the end of July, taking only 5,5 months from start to finish. Spantech delivered a turnkey solution, managing every aspect of the project from initial planning to final installation, including all features and options.

Innovative Hangar Features

The hangar boasts several advanced features. Thermoroof technology, a cost-effective solution, uses a light insulation material that allows natural light to pass through while ensuring the insulated roof liner remains watertight. The high-tech fire protection system includes fire detection cameras, extinguishers, and hoses.

The integration of the vertical fabric door within Spantech frames was carefully designed, with an adjustable hanging system ensuring seamless installation and operations all year round. Additionally, the office space inside the hangar features custom-made containers that integrate perfectly within the building, maximizing interior space.

Throughout the installation, Spantech also supplied high-power electrical distribution, heating and cooling systems, safety lines and a compressed air system.

Engineering for Harsh Conditions

Situated at an elevation of 1000 meters in the mountains of Teruel, Spain, the MRO hangar was designed with permanent engineering to withstand harsh weather conditions. It is built to handle significant snow loads and high wind speeds.

Construction Process

The construction process involved several key stages. Initially, the frame was pre-assembled off-site in Spantech’s production facilities in Germany and Poland. Once fully assembled on the ground, the frame was lifted into place, a significant engineering achievement given its weight and the height required. Following this, the cladding panels were attached to the structure. The installation of the 45-ton doors was another engineering feat, ensuring seamless integration with the hangar. Various systems were then installed, including fire protection, electrical distribution, air compressor, and safety line systems. The final installations included downpipes and the lightning rod protection system.

Benefits of Off-Site Construction

Spantech’s innovative approach and efficient execution of the MRO hangar project for Tarmac in Teruel, Spain, highlight the benefits of off-site construction. Off-site construction allows for simultaneous manufacturing and site preparation, significantly reducing project timelines. The controlled factory environment minimizes weather-related delays, ensuring uninterrupted progress and lower labor costs. Spantech’s off-site construction process adheres to strict quality control measures, ensuring precision and adherence to specifications. Efficient resource utilization and waste reduction are achieved in the controlled factory environment.

Video:

Contact

Avenue Robert Schuman 112

1400 Nivelles

Belgium

- +3227325793