Steelwork & Facade Fixings, Baggage Handling Conveyor Connections, Barriers & Walkways Solutions

| Company | Lindapter International |

|---|---|

| Date | 01.08.2011 |

Terminal 2, Dublin Airport is celebrated with a Structural Steel Design Award from BCSA,  recognising the project’s exceptional design and rapid construction, achieved with the extensive use of Lindapter steelwork fixings.

recognising the project’s exceptional design and rapid construction, achieved with the extensive use of Lindapter steelwork fixings.

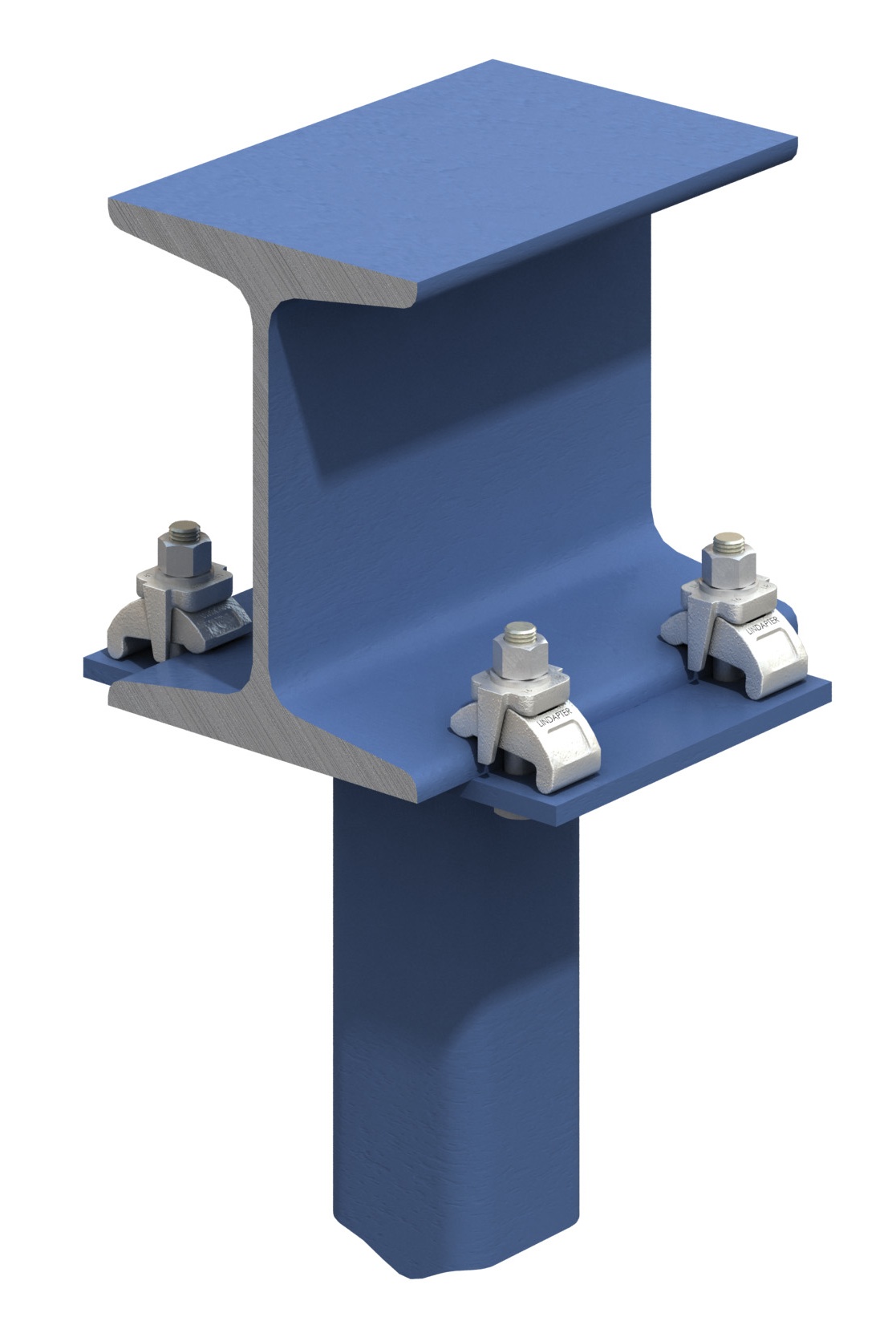

The new terminal comprises of arrivals, departures, check-in buildings and link bridges totalling approximately 12,000 ton of structural steelwork. Lindapter’s innovative no-drill, no-weld connections enabled the fast construction of multiple elements including, structural and curtain walling applications, baggage handling systems and the suspension of building services.

Dublin Airport used a variety of Lindapter products to complete Terminal 2, across a range of diverse applications. Lindapter’s Type LR Self Adjusting Clamp was the most frequently used product. The product’s adjustability to suit a range of different steel flange thicknesses on site meant that a single clamp could be applied to a number of applications. For instance, the Type LR was used to secure baggage handling systems to the structural steel. Lindapter Hollo-Bolts were supplied to a variety of companies working on Terminal 2 for the fixing of both structural steel and aluminium curtain walling whilst Toggle Clamps were also supplied for the suspension of building services.

Naturally, safety and security are a priority at any airport location and conventional cutting, drilling or welding steelwork on site requires the application, approval and issue of a hot working permit, potentially leading to costly construction delays. This entire process can be made redundant with Lindapter fixings, independently approved by safety organisations including TÜV Nord and DIBt, DNV and Lloyd’s Register.

Contact

Lindsay House

Brackenbeck Road

Bradford

West Yorkshire

United Kingdom

BD7 2NF

- 01274 521444