Gandhi Automations Pvt Ltd

Aircraft Hangar Doors For Tough Environments With Extremely Large Openings

Aircraft Hangar Doors by Gandhi Automations are designed for tough environment with extremely large openings. Aircraft hangar doors are available in two form fabric hoist-up doors and Sliding doors. Both offer remarkable advantages for versatility and are suitable for aircrafts in different sizes. Optimum reliability and operational safety are important design principles while designing and installing hangar doors.

Gandhi Automations Pvt Ltd is India’s No.1 Entrance Automation & Loading Bay Equipment Company. This widely recognized position has been achieved over years of hard work, innovation and commitment to quality. Since its inception in 1996 Gandhi Automations Pvt Ltd has been designing, manufacturing, exporting, and distributing products that are problem free and easy to operate. Headquartered in Mumbai the commercial capital of India, the company rapidly expanded its operations, geographical reach, manufacturing capacity and customer base. The sales and distribution network not only cover all the Indian states but also on a worldwide level to over 15 countries spanning Far East, Middle East, Africa, Europe and South America.

The products offered by Gandhi Automations conform to the highest safety standards complemented with reliability and energy efficiency. The product range includes, Hangar Doors, Shipyard Doors, Dock Levellers, Dock Shelters, Rolling Shutters, Fire Rated Rolling Shutters, High Speed Flexible Doors, Sectional Overhead Doors etc.

The company is certified to ISO 9001-2008 and this has resulted in continuous improvement in personnel training, production, inspection, equipment calibration, machinery maintenance, logistics and customer relations. A consistent quality product is the hallmark of Gandhi Automations Pvt Ltd.

Company Profile

-

Hangar Doors

Aircraft / Shipyard Hangar Doors by Gandhi Automations are designed for tough environment with extremely large openings. Aircraft and Shipyard hangar door are available in two form fabric hoist-up door and Sliding door. Both offer remarkable advantages for versatility and are suitable for aircrafts and ship’s in different sizes. Optimum reliability and operational safety are important design principles while designing and installing hangar doors.

We work closely with contractors, architects, and owners and manufacture a system that meets your exact desires or can retro-fit to meet the requirements of an existing structure. Sliding Aircraft Hangar Doors are recommended where no headroom is available and side clearances permitted, whereas fabric hoist Up doors obviates the need for heavy foundation under the door for bottom tracks. The hangar door system is built to undergo enormous wind loads and resist strong weather conditions. A stable operating movement is maintained due to the quality of the work assemblies.

Aircraft Hangar Doors – Quality Engineered

Fabric Hoist Up Doors are electrically operated specially designed doors for sites that do not have space on the side of the door opening for it to slide. This type of door obviates the need for heavy foundation under the door for bottom tracks. The door moves up and down in an aluminum guide with brush seals. It operates by lifting the bottom section upwards and stacking the intermediate sections one on top of the other. The fabric is folded on both sides of the door into pleats.The belt hangar door system is controlled by two straps from the sides of the structure. Belts are coupled to the lower beam, the motor rotates the drum, which winds the belt, and lift the doors. When the drum belts are rolled out, the doors are lowered. These doors have a safety brake, which has two functions: The rupture of one of the belts will stop the movement of the whole structure. After closing the doors, the safety brake blocks movement of the doors – wind lock.

The rope cable doors lifting system differs from belt-operated doors in that the lower beam is lighter. Instead of the two sides of the belt, these gates operated by cables with a pitch of about 2 meters. This allows almost unlimited gate gauges. In addition, the cables are equally distributed over the entire width of the door, not just the edges, it ensures a smooth operation and minimizes the force load of the building.

With each rope cable a dual cable control sensor is installed so that in case of an emergency, rupture or loosening of one of the cables, the door is stopped. Cables are rolled in and rolled out by the drums.

Unlimited numbers of motors depend on the building design and dimensions. In very large sizes, the gate can be divided into several segments, assembling the mullion system.

Hoist up Doors

Gandhi Automation’s Pvt Ltd Fabric Hoist up Door is dealing of hoist up doors and can arrange installation, maintenance and after sales. The hoist-up doors consist of horizontal aluminum or steel profiles on which polyester fabric has been stretched on the inside and the outside. The horizontal profiles are guided in vertical rails, and are 100-1200 mm thick, depending on the door type and wind impact.There is no limitation in horizontal and vertical dimensions of the doors. For very large openings the door can be divided into two or more doors with the help of mullions with load arrestors as a standard version and available in various colors. Each door is equipped with steel ropes or polyester straps (dependent on the door size and type). Polyester hoisting belts are linked to the crush-down protection. The ropes or straps do not touch the fabric thus preventing wearing. The stainless-steel hoist protection is activated and checked on each opening and closing movement. The crush-down protection ensures that a closed door cannot be lifted manually (break-in).

Doors are made of aluminum, and PVC fabric tent are very lightweight, but perfectly suitable for use in aggressive, corrosive environment and extreme weather conditions. These doors are resistant to wind, salt and temperature changes, as well as protection from sand and dust, mould and rot.

Key Features- No sliding rails on the ground

- No clear opening limitations

- Maintenance free

- Wind Resistance – Doors are resistant to extensive wind loads

- Rust Resistance – The doors are capable to resist corrosions

- Electrically operated Fabric Hoist up Doors are specially designed for sites that faces challenge on providing space on sides for installing Sliding Hangar Door

- Fabric Hoist up Door obviates the need for heavy foundation under the door for bottom tracks

- The fabric curtain is a heavy-duty vinyl coated fabric UV stabilized, self-extinguishing and suitable to withstand temperatures between +70 to -35°C

- The door moves up and down in an aluminum guide with brush seals. It operates by lifting the bottom section upwards and stacking the intermediate sections on top of the other

- The fabric curtain is folded on both sides of the door into pleats

- Fabric Hoist up Door is suitable for environments with extreme wind conditions

- The horizontal section transfers the wind load to the vertical guides that are attached to the structure of the building

- The safety features provide 100% security in opening the doors

The large openings where the works by airports and naval ports is a strong issue obtain an easy, quick and safe passage from inside to outside, and vice versa.

With uptime 100%, airports cannot break on time.

Airport hangars must be in continuous service to preserve airplanes from weathering on the runways, then the steepest possible action must be performed by installers who work the final stage of the Gandhi Automation’s product.

The operative processes in an aircraft hangar, and specifically in a hoist up hangar, demand a high level of organization, efficiency and reliability. These requirements have to be fulfilled by the hangar doors to the same extent. Gandhi Automation’s Hangar Doors have been developed precisely to meet these high specifications. That’s why our name is considered as a synonym for hangar doors with:

- permanent operational availability

- best working conditions

- individual project support from the first sketch to the acceptance and during the entire life span

We have a comprehensive experience and expertise. Each door is planned and executed individually for the specific hangar and its utilization.

Gandhi Automation’s Hangar Doors operates as quickly as possible where it is required.

We work to provide Hangar doors with the maximum flexibility, rapidity and wind resistance.

Advantages:

Fabric Hoist Up Hangar Doors are lightweight but durable. They do not need extra heavy support structures like many other hoist-up fabric hangar doors on the market, which significantly helps reduce the hangar construction costs.The hangar door fabric can be equipped with soundproofing, thermal insulation and burglar protection. Fabric Hoist Up Hangar Doors model is the only hangar door on the market with additional thermal insulation. This helps keep down the costs that arise from the hangar heating and cooling. Fabric Hoist Up Hangar Doors is a reliable choice from extremely cold arctic areas to scorching hot climate.

Fabric Hoist Up Hangar Doors fabric features

The hangar door fabric is extremely durable against wear and tear, and it is fixed without rivets. Fabric looks tidy and it is easy to maintain or change in parts with low maintenance costs. The hangar door fabric can be partially or entirely translucent, or it can be equipped with windows. Burglary protection is available as an option.

Fabric Hoist Up Hangar Doors has no size limitations.

Safety

- All doors are equipped with load arresters that instantly lock in position in an unlikely event of a belt or rope breaking. The Giant doors are equipped with crosslinked cables and their individual safety factors

- The doors optionally be equipped with a safety edge along the entire length of the bottom beam to sense anything that obstructs while closing. The door stops automatically and returns to the open position

- All our fabric hoist-up doors are CE marked and comply with the European Union’s product standard for doors, EN 13241-1

Hangar Door Solutions

Hoist-up fabric doors – doors of virtually unlimited size. Because of the light weight and design simplicity, they are assembled very quickly and easily. Each fabric door is designed to meet specific project requirements. Our skilled engineers will design doors to fulfill specific customer requirements, and calculate the wind loads for this design. Our doors do not occupy a lot of usable space. Unlike other manufacturers, Gandhi Automation’s fabric doors do not need much space at the top of the building, so you do not lose headroom. Because of the particular and well-thought-out design, the door folds compactly when raised. Since you lose no headroom, it means smaller building construction costs! Doors can close very big openings, but are very light, so the building will receive minimum loads. In some cases, we recommend the division of a large opening into several smaller ones, using a movable pylons system.This system for your building may be more effective than a single large leaf frame. With a high-speed requirement, the doors can be designed so that the gate would work at higher speeds. This would improve the speed of traffic flow and reduce energy consumption. Fabric doors are made of aluminum and PVC sheet and are very light, but perfectly suitable for use in aggressive, corrosive atmosphere and extreme weather conditions. These doors fit tightly on both sides of the frame and lower beam, are impervious to dust, sand and resistant to wind loads.

Individual options for your specific demand

Each hangar door is an individual solution. You can equip your hangar with exactly the features that you need for an effective operation. Here you can find a range of additional equipment. For requirements which go beyond these, our experienced specialists can develop a bespoke solution. Within our existing setup and installation of hangar door projects, we have already realized many special wishes. Just get in contact with us and let us know your specific need.

Performances- Tail door

The installation of tail doors in your building leads to lower necessary heights of the main bottom rolling door and as a consequence to a reduction in cost

- Door adaption

Special adaptations for the enveloping of the fabric, enable a tight and sealed closure of the hangar door even in the aircraft is too long or too high for the hangar. This is also possible as a posterior adaptation of an existing door, e.g. in case of a utilization of an existing hangar for a bigger aircraft type.

- Integrated staff doors or vehicle doors

Small pass doors are perfect for the personal traffic, the hangar door can remain closed in this case. The solid door features an extremely low, barrier-free threshold

The most important feature in operating a fabric hoist-up door is that the door always stays in an exact horizontal position, even after many years of extensive use.

To maintain this horizontal state even after several years in operation, the condition of the cross-linked steel ropes is electronically controlled and very easy to adjust or tighten.

The cross-linked steel ropes guaranteeing an always horizontal operation of the specified doors

Minimal maintenance creates an operational economy for the installation of fabric hoist-up doors!

Applications:

Aircraft Hangars Sand-blasting and Paint Shops Shipbuilding Panel-line and Module Shops Aluminum Welding Shops Shipyard Modernization Projects All Weather Terminals (AWT) Yacht Building Facilities Exhibition Facilities Stadiums and Sports Arena

-

Sliding Hangar Doors:

Hangar doors are a great option for massive openings, also when exposed to high wind loads, temperature extremes and harsh environments. With almost no limitation to size or configuration, they are the choice for aviation, mining and shipyard industries.

Sliding Hangar Doors are recommended where no headroom is available and side clearances permitted, whereas fabric hoist Up doors obviates the need for heavy foundation under the door for bottom tracks.

The hangar door system is built to undergo enormous wind loads and resist strong weather conditions. A stable operating movement is maintained due to the quality of the work assemblies.

These hangar doors are wildly used, multi-track telescopic mechanism creating possibility of widest opening. It needs less headroom. This type of door can either be bi-parting or uni-directional with each door section bottom rolling and top guided.

Bottom rolling hangar doors are an excellent application for any pre-engineered or custom designed facility. weight of the door is carried by a bottom rail & are engaged in top roller, this mechanical character is allowing doors to withstand more wind load. Properly sealed and insulated panel can protect internal ambiance and cleanliness in types of weather. This type hanger Doors comes with integrated pedestrian doors.

Single or double engines are used depending on the door size. We provide durable sliding aluminium hanger doors, shipyard hangar doors, and aircraft hangar doors for aviation, commercial and industrial applications.

Sliding Steel Hangar Doors – Unlimited Width

- This is a robust steel door for openings of unlimited width and 40 meters or higher. With its state-of-the-art drive systems and choice of multiple safety devices, the sliding hangar is now the door of choice for the latest very large hangars designed to accommodate aircraft, Ships, Mining cranes.

- Full weather sealing is included and there is a virtually unlimited choice of cladding, glazing colours and configurations.

- Gandhi automations manufactures individual and customized hangar door solutions with freely moveable door leaves, telescopic sliding doors or around the corner doors.

- Extra technical equipment, such as tail doors and integrated pass doors without threshold and other doors, can be accommodated with ease.

- operate extremely smoothly – even marginal engine power is sufficient to operate the door and in case of power failure, unproblematic manual opening and closing is possible even with large dimensions.

- Flexible opening widths from one meter to the complete width of the door system are possible due to the easy operation of the door leaves.

- Designed to accommodate special, climatic/environmental conditions that may exist in your area. Wind loading, snow loading, seismic concerns are no problem.

FEATURES

- Ground Facilities: No need any extra ground construction to install and operate the doors

- Sealing Properties: Door has excellent sealing properties, the main reason for the energy efficiency of the door is the tightness. There is almost no draft coming through the door. The Door also has a big pocket at bottom of doors. All side guide rails have rubber sealing materials to supply best sealing at closed positions.

- Safety Features: Warning lights, buzzer, operation lights, cable break photocell, obstacle protection is standard safety feature, will stop automatically if any obstacle while closing down. If cable is break or because of any accident cable is broken, door operation can be overridden and done by a mechanical system of hand crank system.

- Corrosions and Life time: The Flexible giant is suitable for use at harmful and humid areas. Impervious to dust and sand, corrosion resistant. Special fabric chosen is resistant to UV and can save color and properties up to 15 years. Steel support beams are coated with anti-corrosive coatings.

- 5. Maintenance: Very less maintenance requirements another desirable property of the doors besides of sliding door system. If by accident fabric is torn, Only that part of fabric can be replaced. Very few mechanical parts, no greasing is required because of use of polyamide material for moving objects. Only steel cable needs to be periodically checked, once every six months.

- 6.Fire resistance: Material used is fire resistant as per standards

-

Other Products offered by Gandhi Automations include:

Loading Bay Equipment

Gandhi Automations manufactures loading bay solutions like dock levelers, dock shelters, sectional overhead doors. Dock equipment’s are designed and factory-made in state of the art manufacturing facility. Our dock equipment meets international safety standards like EN1398 for dock levelers and product is CE marked.

Further details at: http://geapl.co.in/dock-equipment.html

-

1. Dock Levelers

Dock Levelers are the crucial part of your loading bay area. Usage of dock leveler aids in fast loading and unloading of goods at warehouse, moreover is also important from safety and security view. Dock leveler acts as bridge between loading bay area and truck, height difference between truck and bay area is bridged and material movement can be carried out smoothly between warehouse and truck. We manufacture dock levelers conforming to EN 1398 standards and our product is CE marked. Operation of dock leveler is very easy, unskilled labor can use perform operation with ease.

Salient Features

- Its platform is welded using robotic arm and lip in almond anti-slip steel

- Single effect lift cylinder, double effect lip cylinder

- Security stop in case of unintentional departure of the vehicle. Maximum pressure valve

- Numerous sizes of rubber cushions offered

- Adjacent foot guard steel guards

- Tilt permits Dock Leveler to recompense for canted situation

- Maintenance prop to support Dock Leveler during maintenance checks

Types:

- Radius Lip Dock Levelers

- Telescopic Lip Dock Levelers

- Edge-of-Dock Levelers

-

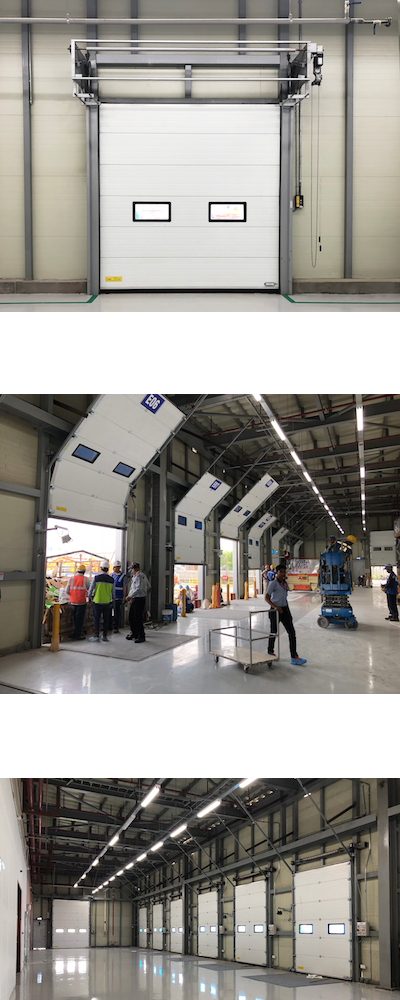

2. Industrial Sectional Overhead Doors

Sectional Overhead Doors manufactured by Gandhi Automation’s are perfect for all logistical and industrial warehouse requirements. Sectional overhead doors are most useful in pharmaceutical industry. These doors help in maintaining controlled atmosphere inside warehouse.

Our Sectional Door design is best for clients who need robust, well-insulated and space-saving doors with security and offer astonishing benefits. Sectional Overhead Door side runners transfer vertically along the wall and parallel to the ceiling, guaranteeing best use of the available inner space. Its heat insulation and soundproofing confirmed by insulated panels, can maintain internal environment conditions and energy consumption. Quality materials, exact processing and constant quality checks promise flawless safety, dependability and long service life. All our doors obey with safety obligation of international standards.

Salient Features

- Pre-painted, galvanised steel, sandwich pane, width 40 mm, 80 mm and 100 mm

- The gaskets, made of a special non ageing rubber, seal the edge of the door opening. They produce a faultless seal, preventing water, air and dust infiltration.

- Small bulk for more space indoors and outdoors.

- Stress-free and real to open and operate.

- Energy savings and more ease.

- Happy indoor environment and good-looking design.

- Sectional Overhead Doors can be customized as Gas Tight Ripening Room Doors.

- Opening – Closing speed = 0.2 – 0.4 m/s.

- Sizes available : Width (max) = 15000 mm.

- Height (max) =10000 mm.

-

3. Dock Shelters

Dock Shelters seal the gap between the warehouse and the container in such a way that when the Sectional Overhead Door is opened material and personnel are protected against the dust, humidity and temperature conditions outside.

Isolating the warehouse environment from the outside, it is not only useful to the human working conditions, but also for avoids entry of dust and heat, therefore resulting in energy saving, ecological safeguard, guard of fragile goods and better working efficiency. Gandhi Automations offers a complete variety of Dock Shelters available for all kind of usage and situation from the outside cold conditions or the chilled ones from outside heat and also from shower, breeze, snow and dirt.

Types:

- Retractable Dock Shelters

- Cushion Dock Shelters

- Inflatable Dock Shelters

-

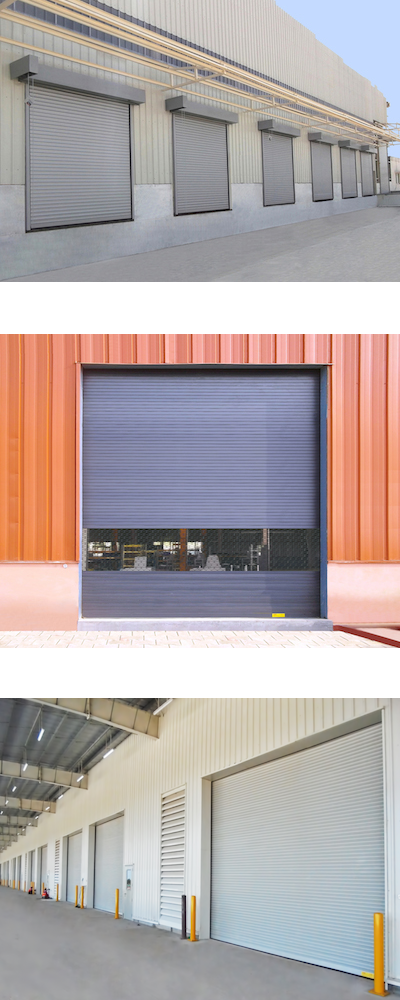

Rolling Shutters

The widespread and broadly used amongst all the categories of doors is the motorised rolling shutter the figurative feature of our motorised rolling shutters is its hard assembly gained due to the use of sturdy metals in the formation of slate and guide profile. This feature performances as a shield and safeguard against theft, damage & hurricanes.

Our motorized rolling shutters are easy to function and confirm client gratification. Our motorized rolling shutters and doors are factory-made in our state of art manufacturing facility and the plant has a capability to produce 6000 rolling shutters in a month.

Motorized Rolling Shutters by Gandhi are typical, are perfect for circumstances where side room is less and security is required. Our Rolling Shutters need very less headroom above the structural opening. They combine strength with elegance along with toughness and are designed for both external and internal applications. Automatic Rolling Shutters are made-up of interlocked Galvalume, Galvanized Insulated and Non-Insulated, Stainless Steel, Patented Aluminum profiles and patented Bright Steel Bar Rolling Grills. Automatic Rolling Shutters are strongly built to endorse trouble-free process and long life. The Motorized Rolling Shutters can also be planned as per customer’s conditions or conforming to IS6248.

All our Rolling Shutters are automatic using vigorous drive expertise with manual override in case of power failure and are dense, noiseless, and dependable with low decibel level.

We can manufacture motorized rolling shutters to a maximum width of 30,000 mm and height of 40,000 mm with boundless array of choices to please both artistic deliberations as well as working prerequisite.

Further details at: http://geapl.co.in/rolling-shutters.html

-

Fire Rated Shutters & Doors

Gandhi Automations fire rated shutters and fire rated doors are designed to protect the facility up to four hours during a fire accident. Fire rated shutter stay open under normal circumstances and close automatically in the event of a fire. Our fire rated doors are designed as per international standards. Our fire-resistant doors can be operated manually.

Further details at: http://geapl.co.in/fire-rated-shutters-doors.html

-

High Speed Doors

High Performance Doors are automatic doors used for fast access between internal and external areas of buildings.

Prime High-Performance Doors are designed and factory-made with German collaboration using state-of-the-art and resourceful engineering technology for frequent use in high traffic areas with opening speeds up to 3 m/s. The high opening speed reduces time taken in movement of material, thus hastening the logistics process. Our team of skilled engineers visits site and recommend the most suitable rapid door to client. Rapid doors are manufactured and installed keeping in mind international standards.

A wide range of Prime High Speed Doors are available for various operations, including areas with special requirements for temperature control, hygiene, storage and handling of frozen foods, Atex rapid doors are need in explosion proof areas, deep freezer automatic roll up door are need in cold storages, warehousing, loading bays and on conveyor systems. Prime Reset features a special advanced self-repairing system.

Further details at: http://geapl.co.in/high-speed-doors.html

-

Product Catalogues and Brochures (click image to download)

Images

Company News

Gandhi Automations presents its ultra-huge Vertical Lifting Fabric Hangar Door at Kuala Lumpur International Airport

Transform Your Hangar with Our Door Solutions | Join Gandhi Automations at MRO Shanghai

Join Gandhi Automations at Airport Show, Dubai, 6th - 8th May 2025

Visit Gandhi Automations at MRO Russia & CIS 2025

Contact

Chawda Commercial Centre, Link Road

Malad (West)

Mumbai - 400064

India

- +91-22-66720200 / 300

- +91-8450977001