MSG Production

Environmental Friendly De-Icing, Aircraft Wash, and Inspection Solutions for the Airline Industry

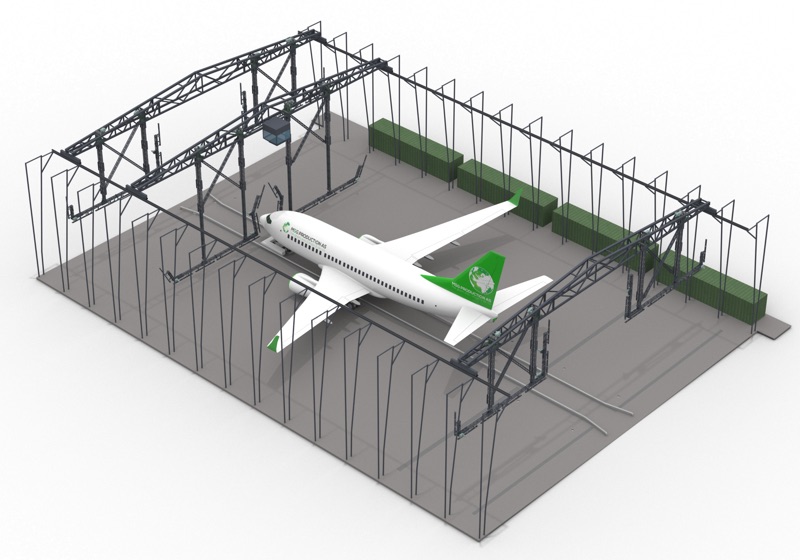

MSG Production has developed an environmental friendly de-icing, aircraft wash and inspection solution which is a completely new way of dealing with the challenges of deicing and washing airplanes.

Our closed automated system gives the airport handlers a safer, quicker and more predictable way of solving these operations, in a way that is a lot more time-efficient and environmentally friendly than other methods.

Our models:

RS-500

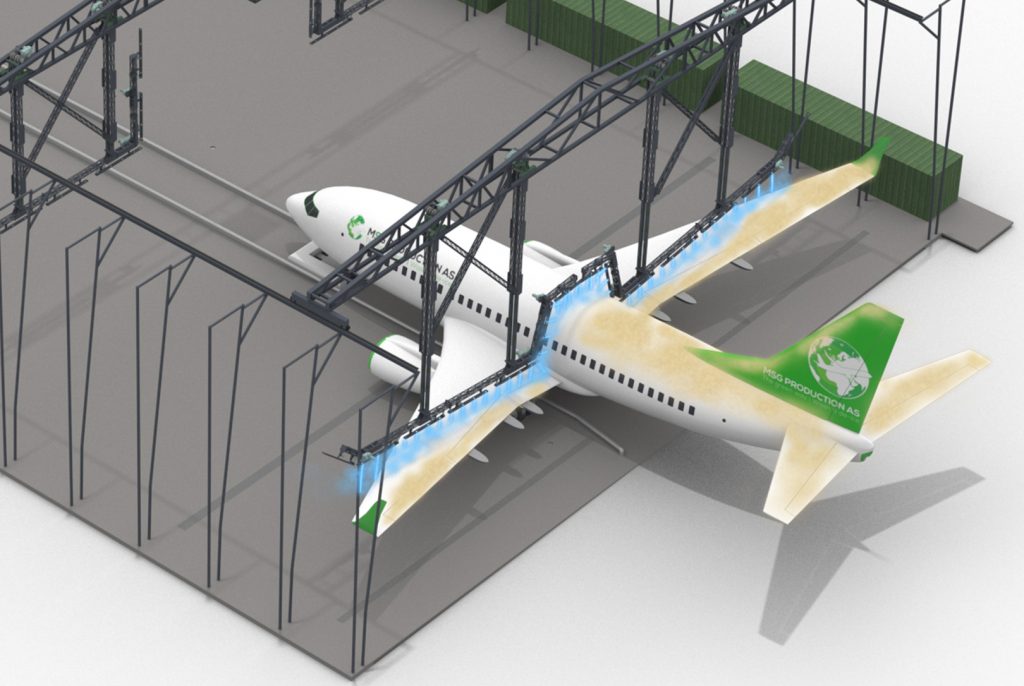

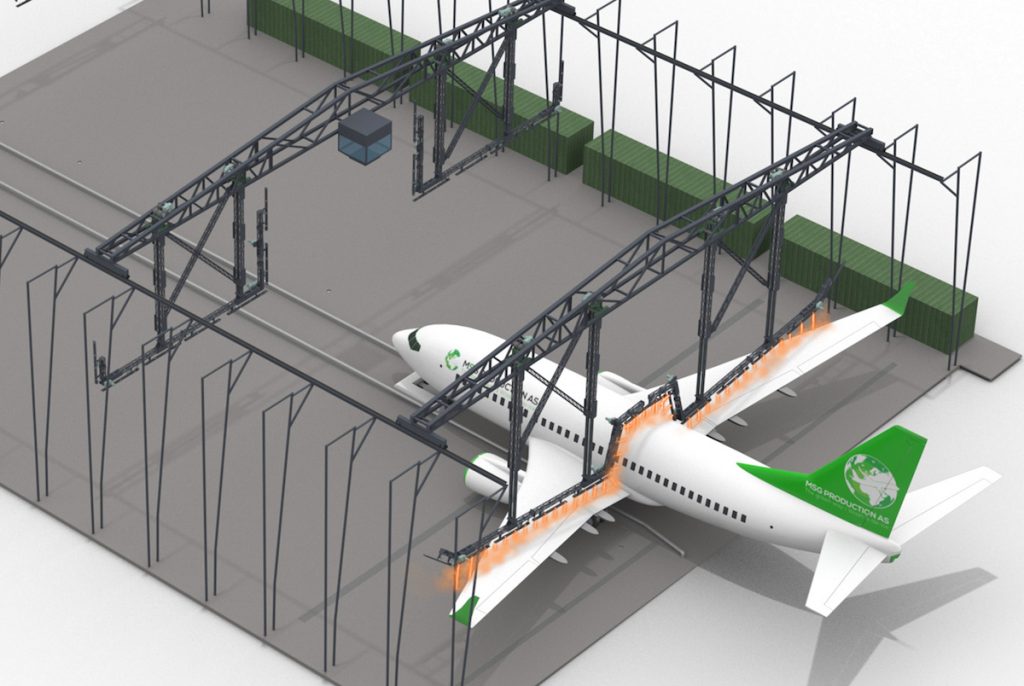

This multiuse model is engineered for deicing, washing and inspection purposes. Fully compliant with industry regulations, a deicing operation is completed in just a few minutes, regardless of weather conditions. All glycol and other fluids are collected and recycled in an underground recycling unit on site. When not in use for deicing, the machine can easily be switched to a washing mode.

RS-400

This model is designed for washing and inspection purposes only. Where traditional washing methods take hours, a full exterior wash of an airplane is completed in less than half an hour using the RS-400. The brushless system offers a safe and gentle method to protect the coating of the airplane.

RS-400S

This model is essentially like the RS-400, but is designed especially for sandy areas and has a functionality well equipped for removing sand from the aircraft body and engine.

All models comes with a complete engine wash as an option.

MSG Production welcomes you to visit our full-scale visitor facility in our own airport in Skien, Norway.

For more detailed information please visit our website www.msgproduction.no

Company Profile

-

De-icing and anti-icing processes

Due to its covered configuration, our system will provide you with a more predictable de-icing performance for your winter operations by de-icing your aircraft in just a few minutes.

The MSG solution will perform de-icing operations with a high level of safety and efficiency, in accordance with existing regulations.

-

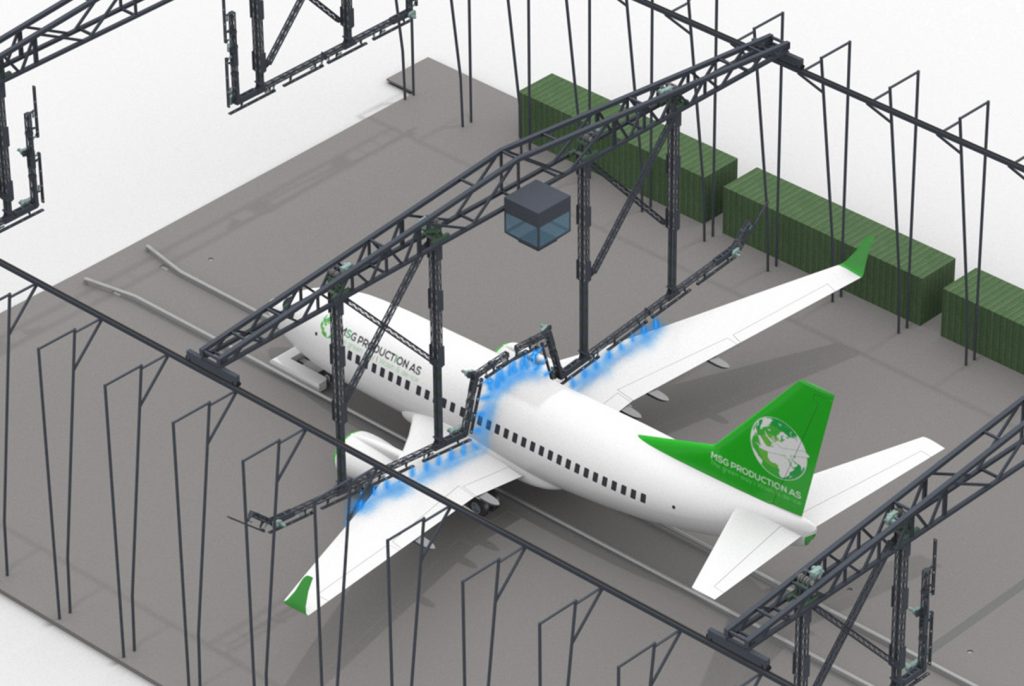

Washing process

Both the RS-400 and RS-500 models offer brushless washing with high precision nozzles performing high pressure over- and under washing of the aircraft.

This automatic system is pre-programmed for each aircraft make and model, and the system will wash according to existing procedures for each aircraft. The washing time is approximately 20 minutes, depending on the aircraft make and model. The chemicals used in the process are biodegradable.

-

Inspection process

Both RS-400 and RS-500 models can be equipped with an inspection camera as an option. We offer multiple solutions for inspection purposes, so please contact us for further information about the options available.

-

De-sanding process

The RS-400S model has a built-in functionality that will de-sand an aircraft quickly and safely. All water and fluids will be collected, recycled and re-used, ensuring a minimum amount of water needed for the process.