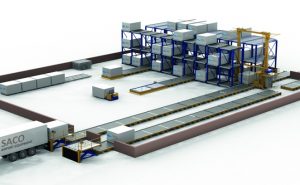

Cargo Equipment (SACO)

| Company | Robson Handling Technology |

|---|

Images

Solving your Cargo handling challenges…

As air traffic continues to grow at a rapid pace of 8% per year, and even up to 20% in some regions, the demand for air cargo transportation is also on the rise. With this surge comes the challenge of effectively managing and transporting cargo to ensure timely and safe delivery.

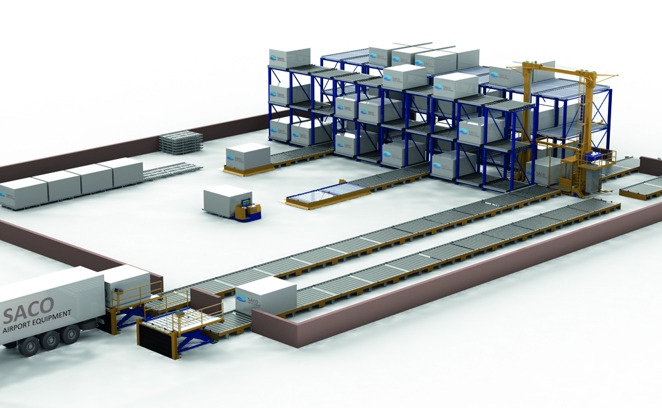

Robson Handling Technology are pleased to be Collaborators, delivery Partners, and Systems Integrators of SACO Cargo Handling Equipment, within the UK and Ireland, offering over 50 years of experience in providing reliable and efficient ULD handling solutions. From manual systems to fully automated solutions, Robson and SACO can design and supply turnkey Cargo Handling Equipment and Systems tailored to the unique needs of each customer.

With modular design units, existing systems can be easily modified, extended, and upgraded in phases as cargo volumes increase. Robson provides full after-sales support, including custom maintenance solutions and 24/7 service to ensure a consistently high standard of performance throughout the lifespan of the system.

SACO’s Cargo Equipment and systems have been successfully supplied and commissioned in various countries including Europe, India, Indonesia, USA, UAE, Canada, Curaçao, Rwanda, and Ethiopia. Trust Robson and SACO to provide the solutions necessary for managing and transporting air cargo efficiently and safely in the face of growing demand.

|

Manual to Fully Automated Solutions – Phased to suit your budgetsStorage / Materials Handling Software and Management Powered Roller track / Truck Docks – with powered lift / Powered dolly docks / Build-up Breakdown powered workstations – with powered lift / Transfer Vehicles / Elevating transfer vehicles / Friction powered roller decks for storage / Ball / Castor Deck / Pallet Stops |

|

System Level 100 – Budget cargo handling system, for manual manoeuvring of ULD’s.System height: 100 mm Components: |

|

|

|

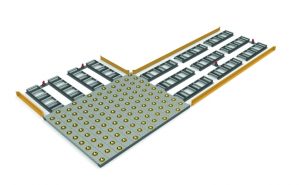

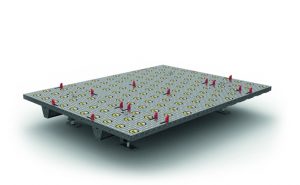

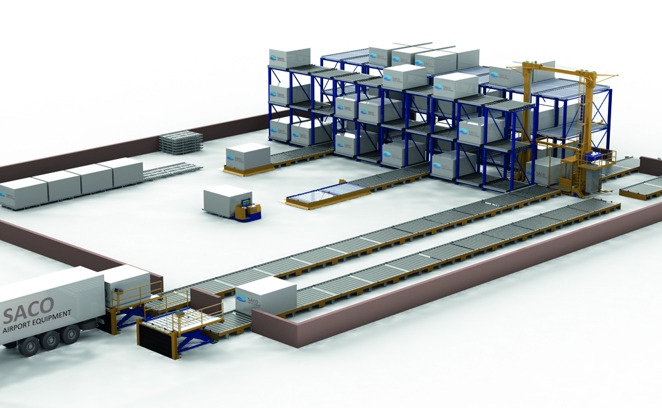

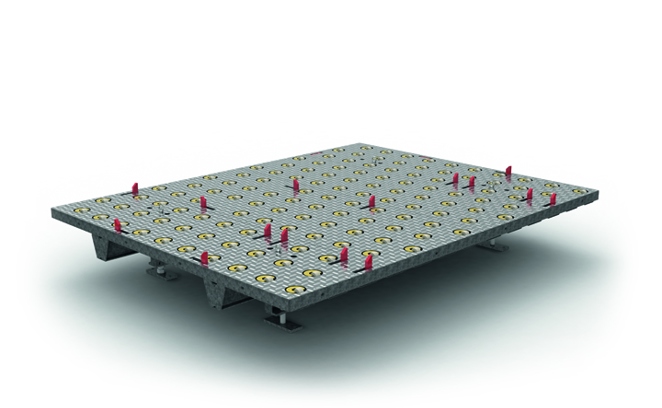

SLAVE PALLET SYSTEM Flexible cargo handling system, for handling of ULD’s.System height: 270 mm |

|

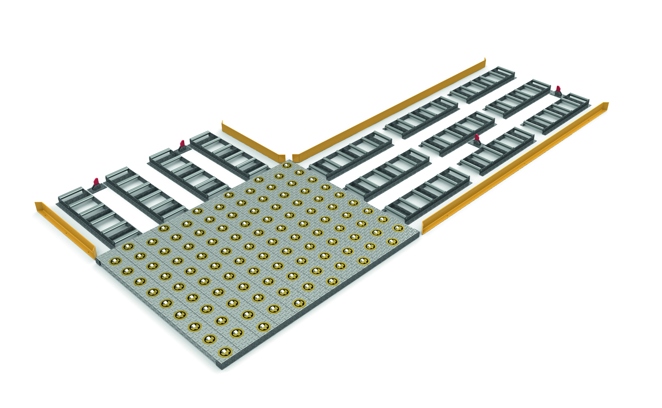

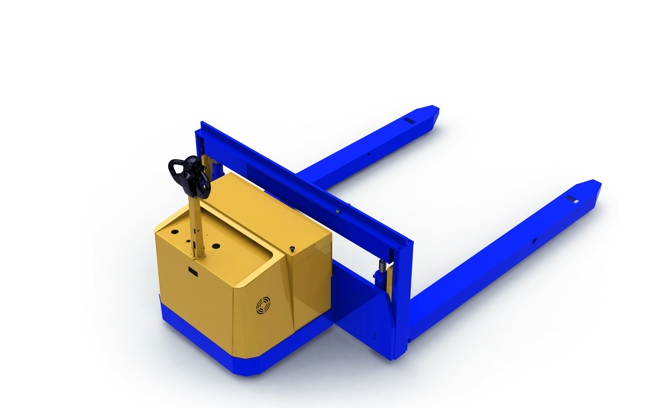

SLAVE PALLET SYSTEM – PALLET MASTER Pallet Masters for manoeuvring of ULD’s on slave pallets Battery powered with 48 VAC system. – RIDE ONTurning circle: Radius 3,200 mm |

|

|

|

SLAVE PALLET SYSTEM – PALLET MASTER Pallet Masters for manoeuvring of ULD’s on slave pallets Battery powered with 48 VAC system – PEDESTRIANTurning circle: Radius 3,200 mm |

|

SYSTEM LEVEL 508 – MANUAL – Cargo handling system, for manual manoeuvring of ULD’s at Dolly height. – Castor DeckSystem height: 508 mm • Roller deck–10ft / 15ft / 20ft NEP / 10ft WEP |

|

|

|

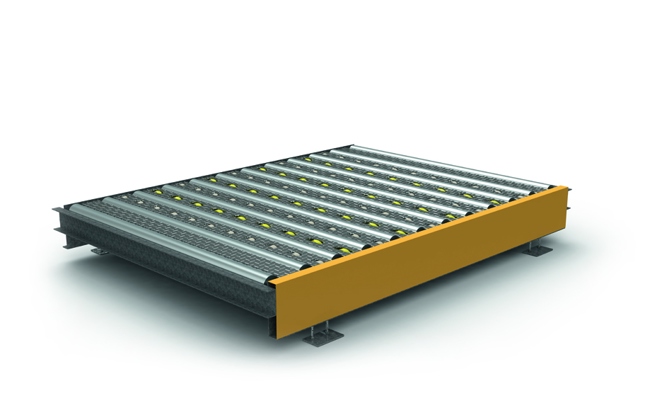

SYSTEM LEVEL 508 – MANUAL – Cargo handling system, for manual manoeuvring of ULD’s at Dolly height. – Roller DeckSystem height: 508 mm • Roller deck–10ft / 15ft / 20ft NEP / 10ft WEP |

|

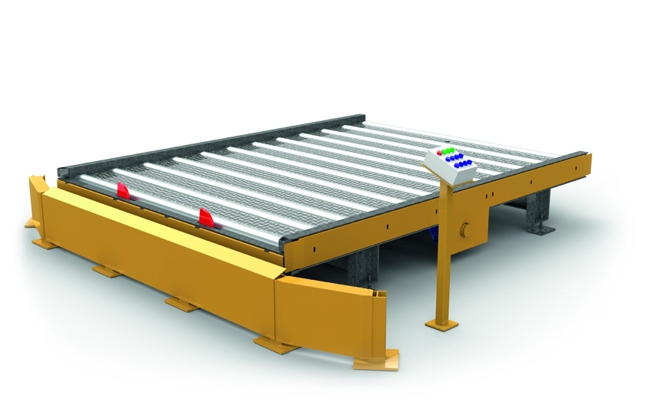

SYSTEM LEVEL 508 – POWERED – Cargo handling system, for automated handling of ULD’s at Dolly height.System height: 508 mm |

|

|

|

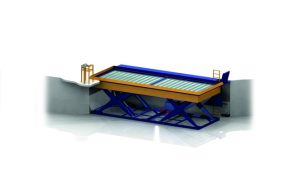

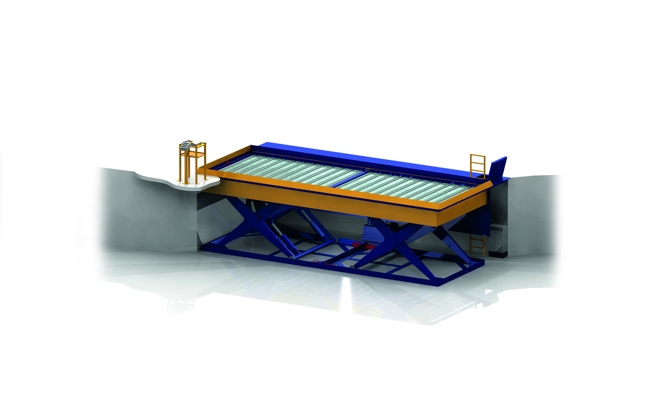

TRUCK DOCKS – Truck docks for loading and unloading ULD’s to and from trucks.Operatingheight: 508 – 1,608 mm |

|

DOLLY DOCKS – Dolly docks for loading and unloading ULD’s to and from dollies.Operating height: 508 mm |

|

|

|

BUILD-UP BREAK-DOWN WORK STATIONS BUBD Work stations for the build-up and break-down of ULD’s.Operating height: 508 mm above floor level |

|

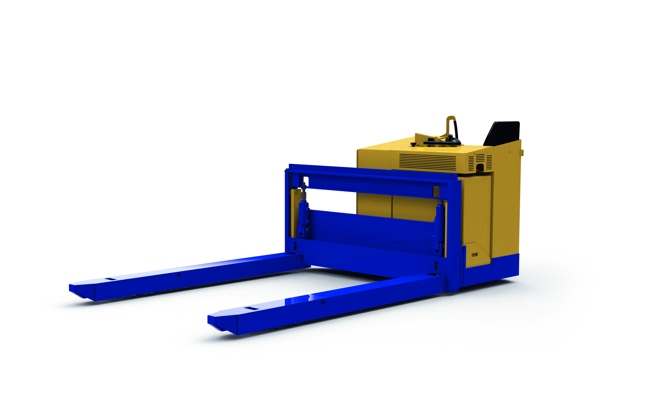

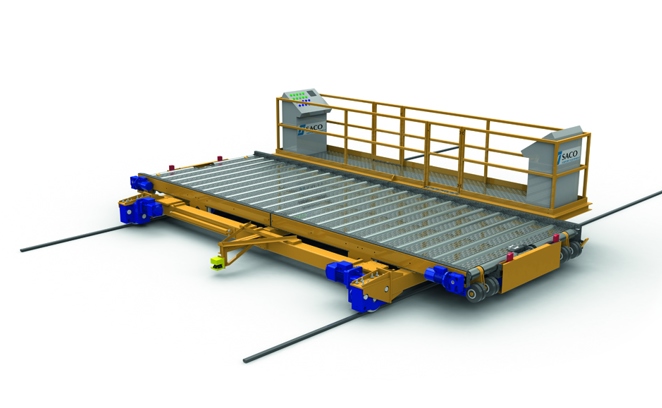

TRANSFER VEHICLES (TV) – Transfer Vehicles for automatically receiving, holding and transferring ULD’s in a single level storage deck system.Operating height: 508 mm |

|

|

|

ELEVATING TRANSFER VEHICLES – Elevating Transfer Vehicles for auto receiving, holding, transferring ULD’s in a multi level storage deck system.Typical operating 1st level 508 mm |

|

FRICTION POWERED ROLLER DECKS – Friction powered roller decks for storage of ULD’s are installed in single level or multi-level racking structures.Operating height: 508 mm |

|