MC 250

| Company | Smets Technology GmbH |

|---|

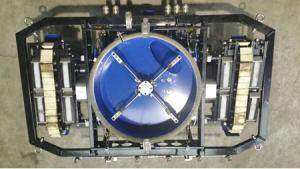

Images

The Magnetic Crawler “MC 250” opens new dimensions in cleaning and preparing steel surfaces by means of high-pressure-water technology. Every kind of larger steel surface, independently of the location (horizontal, vertical and overhead), can be cleaned, de-rusted and de-scaled.

These opportunities make the system indispensable in the shipping and offshore industries, refineries (tank yards) and in the industrial contracting business.

The vehicle is equipped with its own water tank, which allows continuous measurements with a 1 mm thick water-film. The test results can be tracked live. The results are also saved and can be presented in the form of a final report in the Geographic Information System (GIS) environment.

Our Magnetic Crawler features two pneumatically actuated drive modules, which ensure an amazing mobility and maneuverability thanks to rubber covered crawler tracks. A strong and safe adhesion to almost all steel surfaces is guaranteed by a package of 8 permanent magnets which are installed on either side of the tracks.

The “cleaning head” (4 nozzle bars with the gear and the swivel joint) is installed between the drive units (in the standard version). The housing of the “cleaning head” includes a suction connection (DN 50) to fix a vacuum hose and a vacuum device to the crawler, in order to suck of all debris (dirt, old colours, rust and scale).

The “cleaning head” can be installed in front or at the side of the tracks by using an additional adapter kit. This allows the operator to reach narrow areas or corners. The robust crash frame protects the Magnetic Crawler “MC 250” from damage. It is highly recommended to use our safety device “Catcher 25” or “Catcher 40” to prevent the Magnet Crawler “MC 250” of any unnecessary damage, when falling down from the surface caused by wrong operation.

It is very simple and easy to operate the Magnetic Crawler “MC 250”. All functions are controlled from a mobile control panel (see picture above), which is connected to the Magnetic Crawler via a control cable (25m long). In this manner it is possible to control both the pneumatic drive units (tracks) continuously (in terms of direction and speed). Two additional switches are in our control panel available to actuate the “pressure ON/OFF” function and also an “Emergency STOP” function for the high pressure pump.

Knowing that different pump models have different control systems this switches are available but not in function. They can be activated by our customers.

- Working fluid: Water, even brackish and sea water

- Max. water flow rate: depends on swivel joint / approx. 40 l/min

- Max. working pressure: depends on swivel joint / approx. 3,000 bar

- Working width: 250 mm

- Housing width: 300 mm

- Total width of the complete unit: 700 mm

- Total height of the complete unit: (without swivel joint and hose connecting nipple) 280 mm

- Total depth of the complete unit: 450 mm

- Max. water temperature: 80°C

- High pressure connection: depends on the supplier of the swivel joint

- Weight without swivel joint and nozzles: 48 kg

- Number of jetting nozzles: 4 / 8 or max. 12 nozzles

- Air requirement: 25 l/sec – filtered, slightly oiled and dried

- Recommended water filtration degree: 5 μm

- Min. air pressure required: 6 bar

- Control voltage: 24 V