PBBI - Universal Extended

| Company | Hubner |

|---|

Images

The situation

To avoid prolonged ground time during the boarding and disembarking the aircraft, handling processes have to run quickly and efficiently while at the same time being completely safe

Any collision that might occur between an aircraft and the passenger boarding bridge would not only entail enormous costs but would also represent a serious risk for passengers and airport personnel.

Even for well trained personnel using advanced technology, these activities are a challenge – particularly in stress situations.

The challenge

During the process of approaching the PBB to the aircraft there is always the difficulty to stop the PBB at the right position.

If the PBB does not stop at the optimum position, the gap between floor and aircraft is too big, or a clash of the PBB to the aircraft can happen. Both situations are very dangerous. If the gap is too large, passenger can be injured. In the event of a collision, the risk of damages to the aircraft is very high.

Due to the weight of the PBB little movements might cause a swinging of the PBB with additional risks of damaging the fuselage.

Existing designs of floors of PBBs are often not movable and if movable only movements in straight direction are possible. Due to the contour of an aircraft this will cause a gap on the left side.

For standard PBBs it is not possible to dock the canopy system horizontal onto the aircraft while the bridge-head was turned. Using existing floors with tilt correction will cause gaps on the lateral side to the canopy system.

For PBBs without a combination of flexible and extendable floor as well as full unit tilt correction the driver need to be well trained to avoid the risk of damages or longer time for the proper approaching.

The solution

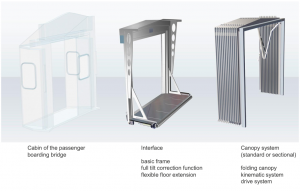

HÜBNER has developed the PBBI – Universal Extended with full unit tilt correction and flexible floor extension that minimizes the exerted force in contact with aircraft and conforms to all normative standards.

The PBB will be stopped by the drive unit with a distance of approx. 100 to 150 mm in front of the aircraft. This will ensure a safety distance of the leading edge of the platform to the aircraft avoiding any contact and therefore damages to the fuselage.

Driven by gas pressure springs the flexible floor extension will afterwards be pushed out and the floor is sealing the fuselage following the contour over the entire width.

Only a minimized pressure will be applied to the fuselage (HÜBNER soft-touch design).

Also the horizontal adjustment of the floor is covered by a special full unit tilt correction which also pivots the canopy for best sealing, too.

If the tilt correction functionality is not necessary (e.g. for nose-loader-bridges) a PBBI – Single Floor Adjustment with flexible floor extension covering the same safety features is available.

PBBI – Universal Extended is the most safest and comfortable floor for the bridgehead of the PBB

HÜBNER soft touch floor

HÜBNER soft touch floor

– damages are excluded

– only minimal pressure to fuselage

– sealing over entire width

– sealing over entire width

➔ Maximum safety

➔ drive unit stopps PBB with safety clearance to fuselage

➔ no deformation of floor bumper

➔ no objects can fall onto apron

➔ fire penetration from below is prevented or significantly reduced

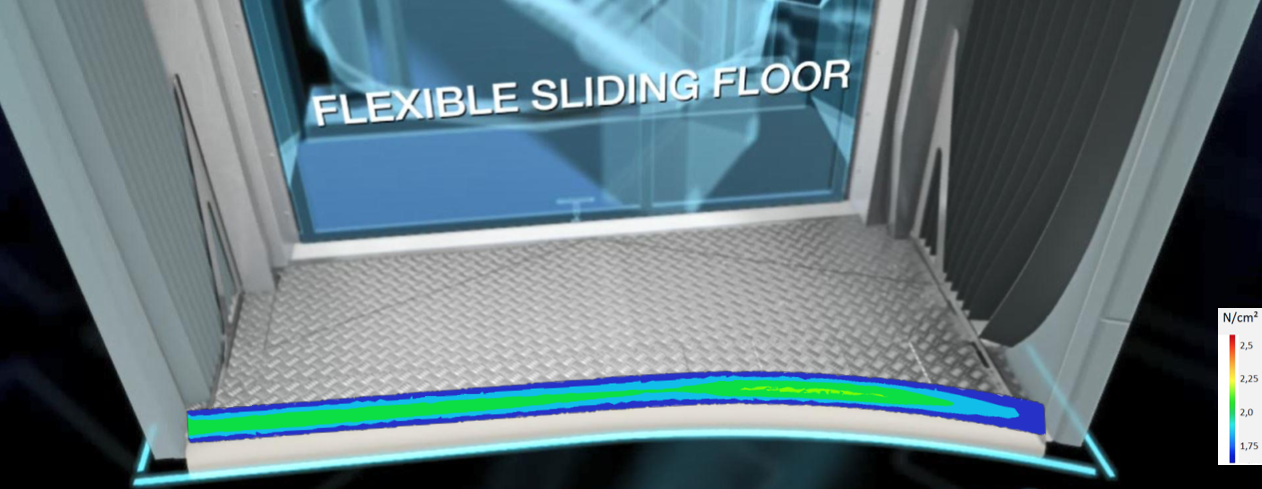

Distribution of contact pressure of a HÜBNER flexible sliding floor (at A320 example)

Requirement acc. to DIN EN 12312-4:2014-07:

“The static force equivalent should not exceed 1500 N distributed over the length, or 1500 N on any 100 mm x 100 mm contact area.”

Permissible average for length of flexible sliding floor (L = 3240 mm): 2,32 N / cm2

Max. value acc. to DIN EN 1312-4:2014-07: 15 N / cm2

Soft-Touch Floor

The soft-touch design of the flexible floor extension will be pushed out by 5 gas springs to the fuselage.

Maximum static force of the 5 gas pressure springs is in total 1200 N: left side / right side 300 N each, 3 inside 200 N each.

To retract the floor there is one motor installed and the floor will be pulled back by means of belts The flexible bumper will be leant to the fuselage applying a minimal pressure.

Vertical movements of the aircraft will be counterbalanced automatically.

Touch-less docking:

(small) gap between platform and fuselage will reduce or even lose stability of PBB due to the long overhang from the drive unit to the leading edge, there is a risk that the PBB might start swinging by walking passengers and/or wind if there is no light contact with the fuselage due to swinging PBB damages cannot be excluded

HÜBNER soft touch floor

– gently leaning

– spring loaded system

➔ Stability remains

➔ keeping stability of docked PBB

➔ counterbalance of vertical aircraft movements

Advantages of the PBBI – Universal Extended

- Damage to the fuselage will be reduced tremendously

- Maintenance free

- Closed flooring, no gaps between flooring and folding canopy (lateral)

- The full unit tilt correction will dock the canopy system horizontally onto the aircraft

- Easier handling of difficult airport positions due to the full unit tilt correction as well as flexible floor extension; better adjustment options for the bridge-operator

- Spring powered sliding floor with 400 mm extension and flexible bumper; retraction by electrical motor and belt drive

- Soft-Touch floor design for minimal pressure to the fuselage

- Flexible and extendable floor follows the contour of the fuselage over the complete width

- Suitable for A380 main- and upper deck

- Modernization of installed Passenger Boarding Bridges to fulfill future requirements

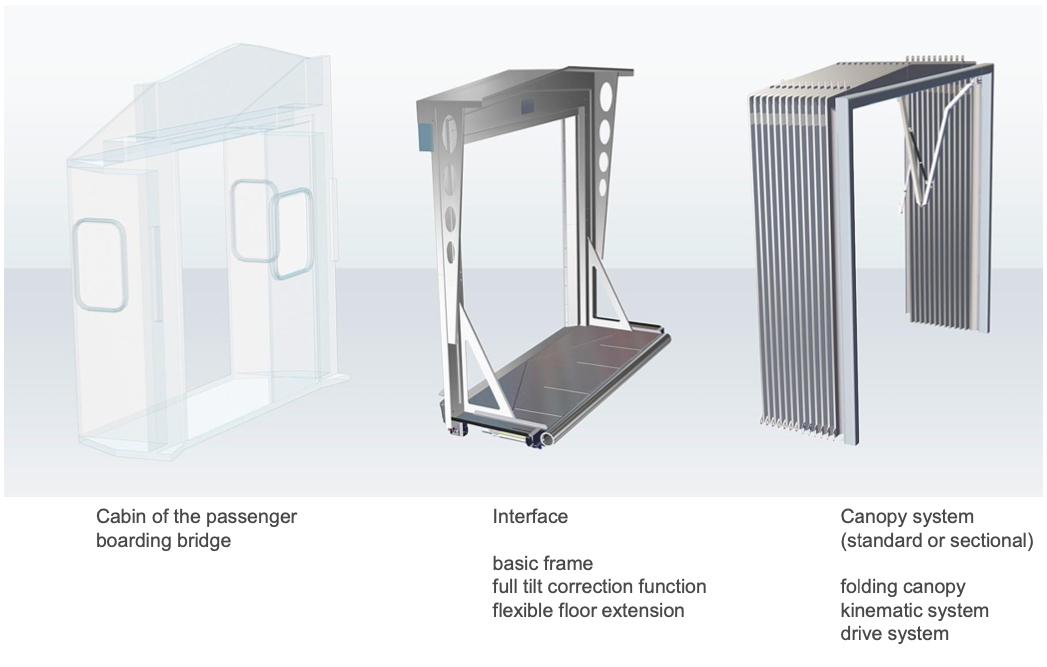

- Adjustment of the PBBI – Universal Extended to every passenger boarding bridge possible

- Could be delivered in pre-assembled parts: small packaging dimensions, low transport costs, easy handling

Technical data of the PBBI – Universal Extended

- Extendable floor: extension 400 mm over the complete width of the floor

- Flexible floor: 5 segments to follow the contour of the fuselage over the complete width

- Tilt correction movement: 0° to 6° (standard), -3° to 3° (optional), -3° to 6° (optional)

- Total weight: 850 kg (including the canopy, kinematic and drive system); excess load to the PBB will be very low

- Operating Temperature: -30°C to +80°C

- Soft-touch floor design for minimal pressure to the fuselage

- Optional: floor bumper equipped with additional safety limit switch to avoid clash of PBB to fuselage

- Optional: floor equipped with heating system to avoid icy, slippery floor surface

- Optional: additional sensors to operate further features of the PBB are available