Modular Rollerbed System for Warehouses

| Company | Joloda Hydraroll Ltd |

|---|---|

| Product code | Modular Rollerbed Systems for Warehouses / MRS Warehouses |

Images

Modular Rollerbed Systems

Joloda Hydraroll’s range of modular roller systems are a diverse and innovative solution. Our systems are proven to make your logistical processes as easy and dynamic as possible to save you time and money to make your business more efficient and profitable.

Our innovative solutions have seen us specialise in the entire logistical process, from moving cargo around factories, warehouses and airports, to moving loads through docking bays, into vehicles such as trucks and vans.

Our modular roller systems have a variety of different applications. We’ve assembled a suite of different brochures to help you understand how to streamline your logistics processes and create the ideal solution to your loading problems.

Introducing The Modular Rollerbed System for Warehouses

Our modular rollerbed systems are simply mounted on top of the existing warehouse floor and can convert any regular warehouse floor into an air cargo handling station, without any civil works.

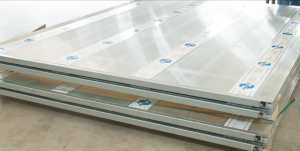

The system consists of multiple lightweight aluminium frames that are interconnected and equipped with lanes of rollertrack that feature a pneumatic rise and fall function for handling ULDs, PMC pallets, and block pallets.

Modular rollerbed design

The design of the frames is based on aluminium floorboards, which feature pneumatic rise and fall rollertrack modules. No welding is required to make a frame.

The front and rear of the frames are closed by zinc plated steel profile which are screwed to the warehouse floor.

The frames are supplied partly pre-assembled and ready for installation. Our platforms can be specified in different configurations, which together, form a complete system.

Frames and Fixings

The modular rollerbed system frames can be fixed straight onto the concrete floor with galvanized steel clamping brackets and chemical anchor bolts. Whilst heavy-duty ‘L’-shaped protection strips help to protect the frames from forklift traffic.

System Controls

As the modular rollerbed system pneumatically rises and falls, the system can either be connected to the facility’s compressed air system or be connected to a mobile 400-volt compressor unit. Control units come with a built-in air pressure regulator.

Depending on the layout, length of the system and the number of air sections, the system can either be operated from a manual or an electric pneumatic control panel. The system’s design allows each frame’s rollertrack module to be controlled individually and multiple control panels can be specified to control specific parts of the system. This means that the system can be designed as per your specific requirements.

Safety Features

Heavy-Duty impact Zone with One-Way Pallet Stops – The first frame of the modular rollerbed system is typically located on the outside of the loading dock door. We call this section the ‘transfer platform’. The length of this frame is determined by the distance between the shutter door and the end of the loading bay. The design includes a cut-out for the roller shutter door, so no modifications to the door are required.

This first frame also features integrated pallet stops. This is an additional safety feature that allows pallets to roll in one direction only. When unloading cargo from trailers, the pallet stops prevent ULDs or PMC pallets from rolling into the loading bay door or off from the loading dock. If the modular rollerbed system is used for loading processes too, the pallet stops can be manually lowered to allow the cargo to roll from the warehouse into the trailer.

Forklift Protection Strips

To protect the system against damage from operating forklifts, the delivery comes complete with heavy-duty ‘L’-shaped protection strips around all the open sides, which are powder-coated in bright yellow so they’re easily visible by forklift operators. The forklift protection strips also act as pallet guides and prevent cargo from rolling off the rollerbed during operation.

Emergency Release Points

As a safety feature, emergency air release points can be specified at various locations alongside the frame. If an emergency button is pressed, the system will release air pressure out of the frame’s pneumatic airbag system to lower the rollers and bring any cargo to an immediate stop.

Electric Winch

Electric winches can be specified as part of the modular rollerbed system to pull cargo out of trailers or along the frames. This is especially beneficial to help load or unload cargo safely if there is a slight incline or decline on either the rollerbed or in the trailer.

Recessed Pockets

Recessed pockets can be specified as part of the modular rollerbed system with cut-outs for forklift sprockets to allow the forklift to place either ULDs or pallets on the frames or onto the forklift. These are unavailable on the transfer platform.

Loading Dock Trailer Guides

Loading dock trailer guides with (or without ramps) can be specified as part of the modular rollerbed system to guide the trailer accurately into the loading dock, whilst ramps will raise the height of the trailer bed to match the height of the loading dock.

Slave Pallets

Ultra-low height slave pallets can be specified as part of the modular rollerbed system to safely load and transport ULDs and PMC pallets into and around the warehouse, without damaging either the cargo or the frames.