Access Platforms for Production Lines – Transport, Handling and Storage Systems

| Company | CTI Systems |

|---|

Images

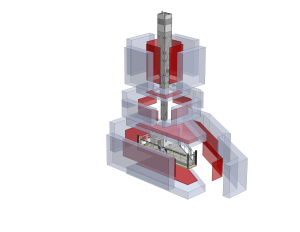

Access Platforms – for aircraft production lines

Designed to operate at different heights and offered with a choice of load capacities

CTI Systems’ range of work platforms includes models that are perfect for a variety of assembly line tasks, such as working on the fuselage, wheel well or landing gear, engines, wings and tail fins.

The designated work platforms guarantee a safe and stable working base. To ensure that production workers can work comfortably and safely at all times, a range of equipment can be integrated into the design of a platform. These include:

- Electrical power sockets and lighting

- Connections for compressed air and breathing air

- Hot and cold water supply

- Vacuum system

- Ventilation devices

- Safety ropes and harness

- Folding railings

- Extendable & foldable platforms for greater working radius

- Interface to MES & ERP systems

Transport and Handling Systems

Optimal support at any stage of aircraft’s production process

CTI Systems offers an extensive range of devices and equipment to support every stage of an aircraft’s production process – from the safe movement and transfer between production lines of bulky fuselage sections to the accurate and timely line-side delivery of component parts for final assembly.

CTI Systems’ collection of transport and handling products includes:

- Interface racks

- Rotating and elevator stations

- Mobile racks

- Cargo boarders

- Crane units

- Mono- and bi-rail systems

- Automated guided vehicles (AGVs)

All processes – whether manual, semi- or fully-automated – are adaptable, so any size or shape of component can be handled, while predefined interface technology allows a seamless integration with the existing MES & ERP systems.

Storage Systems

The large and often sensitive aircraft components must be able to be carefully transported and safely stored in production buffers within a production facility or assembly hall.

With its extensive product portfolio, experience and expertise, CTI Systems delivers customized turnkey intralogistics solutions that meet the requirements of aerospace customers worldwide.

With its experienced aerospace design and construction capabilities, CTI Systems accompanies its customers from the beginning. Based on this partnership, functional and cost-efficient solutions are developed and implemented – with a single supplier.

The CTI Systems suite of storage solution products includes:

- High-bay warehouses

- Stacked warehouses

- Floor warehouses

- Suspended warehouses

- Overhead cranes and manipulators

- Floor-based and overhead conveying systems

- MGV & AGV

CTI Systems’ automated stacker cranes can handle loads weighing from as little as 100kg up to 40 tonnes and they reach speeds of 200 metres per minute.

All storage systems developed by CTI Systems are fully automated and can be integrated within existing facilities as well as new-build sites, while CTI Systems’ warehouse management software has predefined interfaces for the customer`s MES or ERP systems.