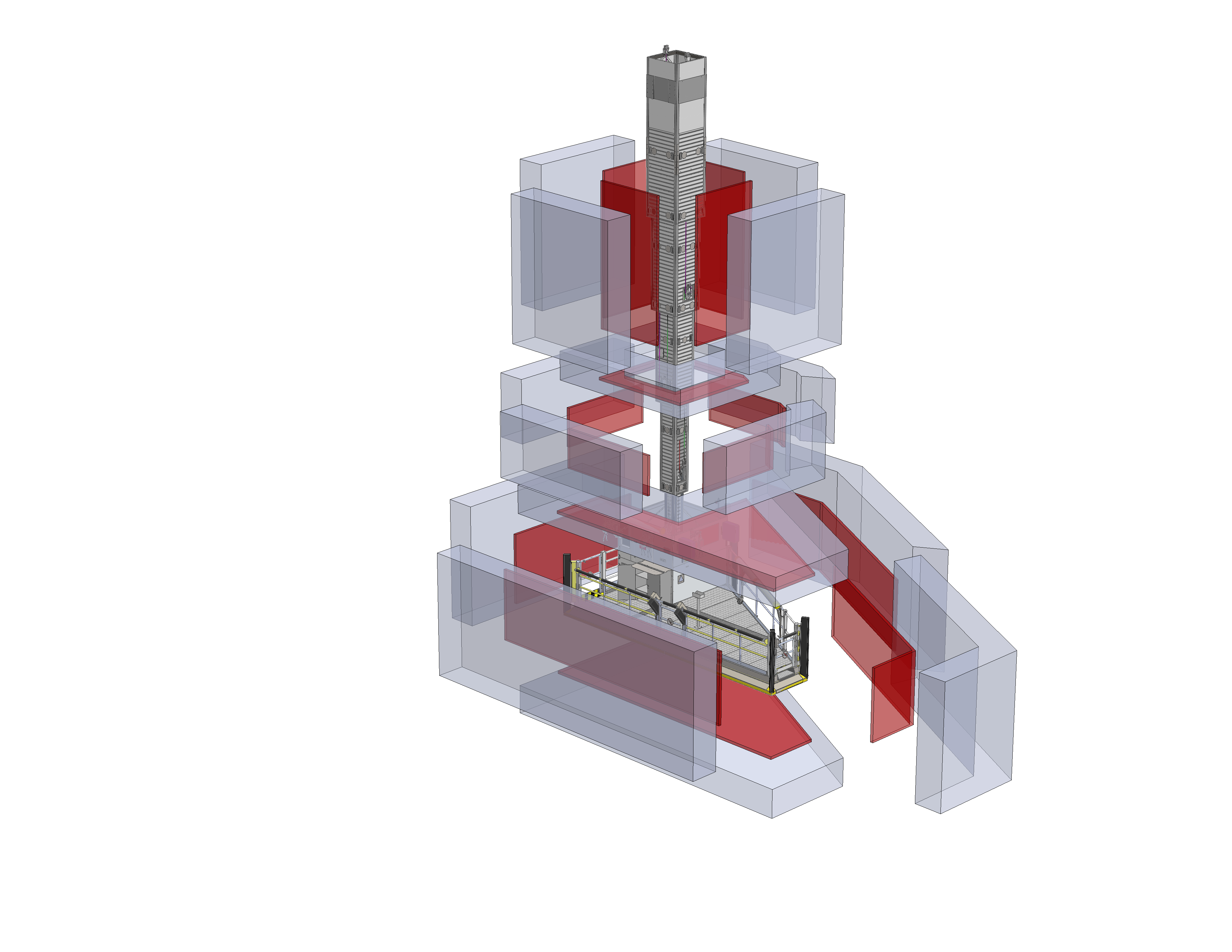

ITP – the Intelligent Teleplatform & Robotic Painting

| Company | CTI Systems |

|---|

Images

Safety, Ergonomy and Efficiency

CTI Systems is constantly investing in the development of new and innovative technology that will help to make its products safer, extra efficient and more ergonomically advanced.

Newly developed digital features integrated into CTI Systems’ iTP family of “smart teleplatforms” help significantly reduce the likelihood of a teleplatform coming into contact with an aircraft.

By allowing the operator to focus its attention on the tasks to be performed instead of steering the equipment, the state-of-the-art iTP range delivers a considerable reduction in the user’s operating costs.

The new features range from a proximity recognition hardware up to a sophisticated software-based distance control system.

They include:

- Twin Scan Control

Since 2020 our Twin Scan Control technology is successfully in use with global OEMs, to the full satisfaction of the operators. It is a common standard for customer inquiries. This technology allows a teleplatform to approach an aircraft with the very highest precision. The system utilises a full scan of an aircraft to restrict the travel speed of a teleplatform and will also bring the equipment to a controlled halt it comes within a pre-set distance of the aircraft’s shell – thereby eliminating the risk of contact between the teleplatform and the aircraft at any time.

Robotic Painting Technology

The traditional way of painting an aircraft is being revolutionised by the development of advanced, robotics-based paint application systems that enable the surface treatment and finishing processes – including tedious and time-consuming tasks such as sanding – to become a fully automated operation.

Robotic painting technology not only sets new standards in the quality of the paint finish achieved, it also presents a number of environmental benefits to the aviation sector. For example, while the optimum paint thickness is always applied, paint waste is significantly reduced thanks to the fact that overspray is minimised. And, because less solvents are used, robotic painting cuts the number of volatile organic compounds (VOCs) emitted in to the atmosphere.