Work Platforms in Test Beds and in MRO Centres

| Company | CTI Systems |

|---|

Images

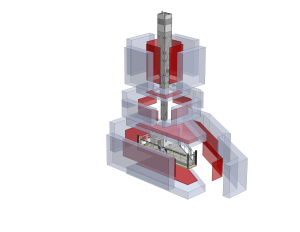

Work Stations in Test beds:

To allow personnel to fine tune engines between test runs within the test cell, access is provided by a scissor-lift work platform that raises workers to the height required to carry out modifications to the engine as it sits in the thrust stand safely and in the most ergonomically comfortable way.

When retracted, the lift’s mechanism is designed to fold down into a pit – leaving the surface of the platform flush with the floor of the building.

Mobile equipment upto as 16ton can travel across the platform when it is in the retracted position.

Work Stations for MRO – Safe and efficient working throughout the shift

Whether as a stand-alone workstation or integrated in a flow line:

The ergonomic design of CTI Systems’ range of workstations ensures that personnel perform safely and at optimum efficiency throughout the course of their shift.

CTI Systems offers:

- integrated work and transfer stations;

- height adjustable workstations;

- work stations that allow staff to operate under suspended loads;

- twin (2) hoist engine carrier options;

- monorail hoist carriers that ease LPT and the compressor assembly or dismantling processes

CTI Systems’ integrated flow line workstations deliver:

- The best worker ergonomics through a height adjustable dedicated work space, therewith:

- Improved work quality;

- Increased work safety thanks engines transfers and components on assigned carriers throughout the process;

- Combined transfer and lifting processes;

- The ability to change over the manufacturing process in less than 10 minutes: CTI’s integrated assembly line workstations allow users to achieve SMED (Single Minute Digit Exchange of Die); therewith:

- Fastest turnaround times (TAT).