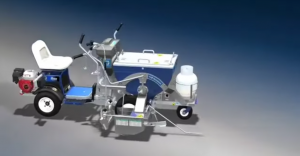

ThermoLazerTM Thermoplastic Striping Range

| Company | GRACO BVBA |

|---|

Images

In areas with heavy traffic, the durability of road marking is a key priority. Airports have a high volume of traffic every day. Traffic control typically needs to reduce flow obstruction to a minimum. Using thermoplastic material has proven to increase the long term quality of the line over regular paint.

The record drying time of this application contributes greatly to smooth traffic conditions. Graco’s ThermoLazer family with technologies like on-board melting system and SmartDie applicators don’t just simplify the process, they also offer the control you need of expected line thickness.

Key benefits:

- Direct Heat System

- Direct flames and an on-board hand torch deliver maximum heat resulting in maximum material flow

- Easy-to-fill Material Kettle

- Available in a 90 to 135 kg kettle matching perfectly to the 18 to 40 kg bead hopper for superior flow

- Adjustable Front Pointer

- Easily adjusts for all size dies for following all marks and creating straight lines

- Adjustable Handle to support multiple heights

- Bead Dispenser

- 30 cm dispenser with 2.5 cm increments allows you to “dial-in” the drop rate

More Information:

www.graco.com/striping

https://www.graco.com/gb/en/products/product-families/thermolazer.html

- Fuel: LP gas

- Main Burners:

- 30000 BTU (200TC/300TC)

- 100000 BTU (ProMelt)

- Material Capacity:

- 90 kg / 200 lbs (200TC)

- 135 kg / 300 lbs (300TC/ProMelt)

- Melt Time for full capacity:

- 4-4.5 hours without a premelt system (300TC)

- Less than 1 hour (ProMelt)

- Bead Hopper Capacity:

- 18 kg / 40 lbs (200TC)

- 40 kg / 90 lbs (300TC/ProMelt)