System Level 508 Powered – Motor Powered Roller Deck

| Company | SACO Airport Equipment |

|---|

Images

System Level 508 Powered – Motor Powered Roller Deck

Motor Powered Roller Deck (MPRD)

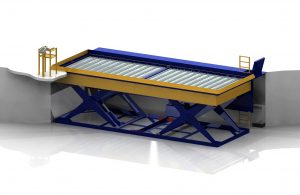

Motor powered roller decks are used for automatic conveying and/or storage of ULD’s. They can also be installed on truck docks, build/break workstations, (elevating) transfer vehicles, etc.

10 ft roller decks can accommodate ULD’s of maximum 10 ft base size with dimensions: L x W: 125 x 96 inch (3,175 x 2,438 mm) and weight 15,000 lbs (6,800 kg).

NEP (Narrow Edge Position) roller decks are suitable for conveying ULD’s with the narrow edge leading.

WEP (Wide Edge Position) roller decks are suitable for conveying ULD’s with the wide edge leading.

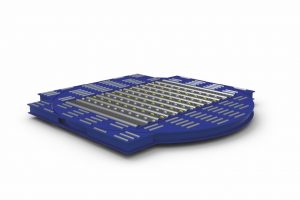

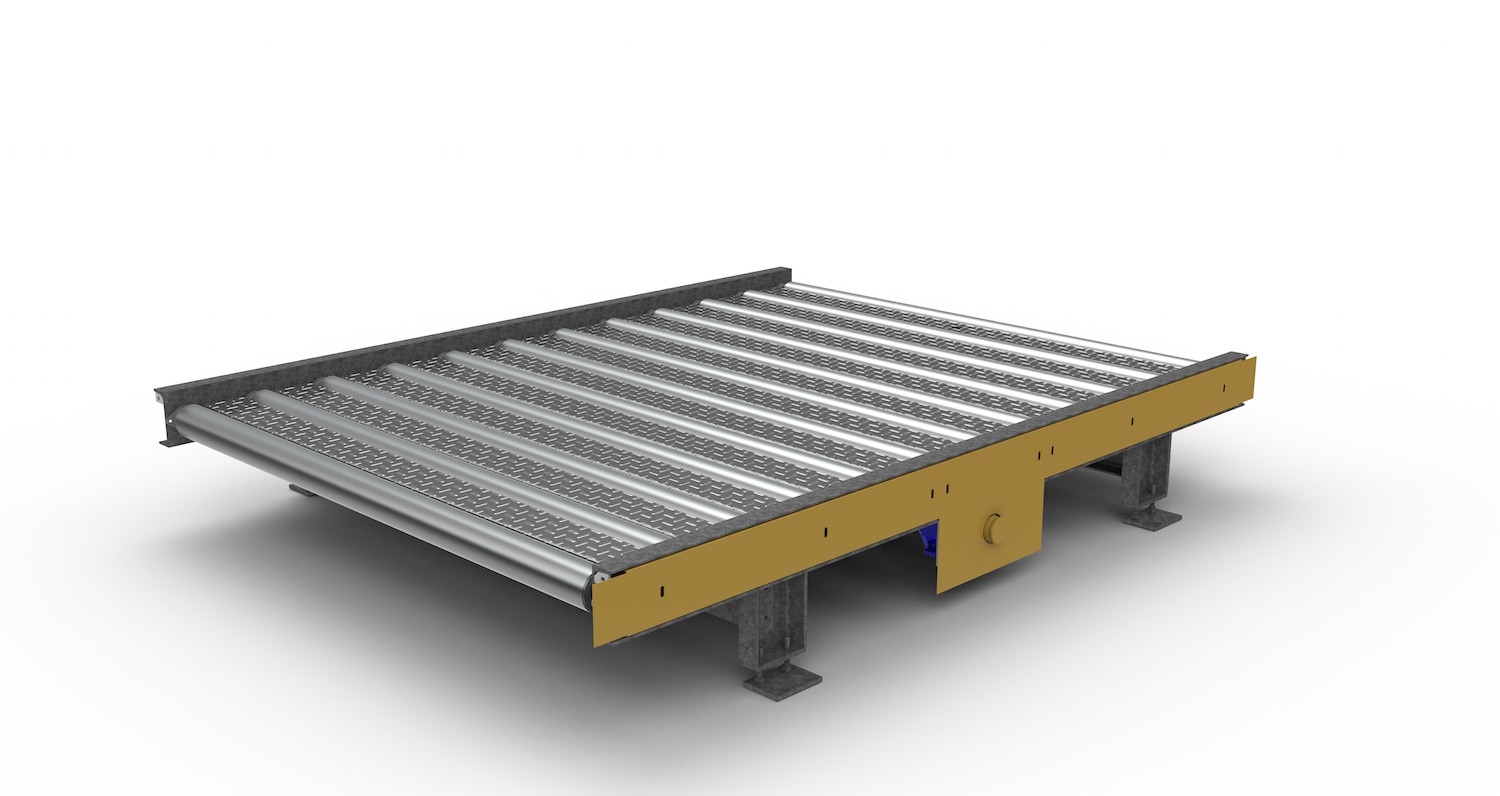

The hot-dip galvanized frame consists of 220 mm high longitudinal steel channel sections and cross-bracings to provide a rigid frame. The upper portion of these sections extend 50 mm above the top of the rollers and act as side guides. Lead-in flares are provided where required to guide ULD’s into position and minimize impact loads.

The full width zinc plated rollers run in sealed and permanently greased spherical bearings. The rollers are linked by means of chains and sprockets, placed outside the supporting beams of the rollers. Sprockets and chains are engaged over 180°.

Each roller deck is powered by an electric motor with brake and gearbox unit which can stop a maximum load within 100 mm and prevent motion once the load has stopped.

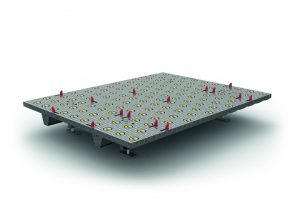

All drive elements such as chains, sprockets, etc. are protected with removable sheet metal covers in such a way that these elements cannot be touched without removing covers. Non-skid walkways are installed between the rollers.

The roller deck is equipped with adjustable supports to be bolted to the floor.

Where applicable, the roller deck is equipped with a photo sensor to detect the ULD position on the deck.

Weighing System (optional):

The roller deck can be fitted with an integrated weighing system equipped with:

- 4 heavy duty stainless steel load cells, beam type, 50 kN capacity

- Junction box and weight indicator for display of tare, net, and gross weights.

The weighing system will be calibrated and verified at site after installation.

Weighing capacity 8,000 kg with 5 kg divisions.

If you need more information or have any questions, please do not hesitate to contact us at info@saco.aero

- Operating height : 508 mm

- CAPACITY – SAFE WORKING LOAD: 6,800 kg

- FINISHING:

- Frame, walkways: Hot-dip galvanized

- Rollers: Zinc plated

- Chain guard: Painted, RAL 1007 (yellow)