System Level 508 Powered – Transfer Vehicle & Elevating Transfer Vehicle

| Company | SACO Airport Equipment |

|---|

Images

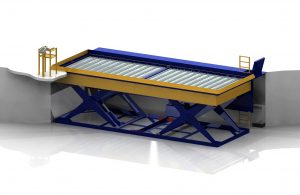

System Level 508 Powered – Transfer Vehicle & Elevating Transfer Vehicle

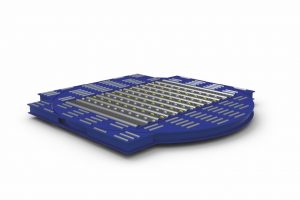

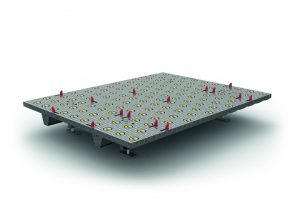

The TV is an automatic/semi-automatic/manual operated type vehicle designed and designed to receive, hold and transfer ULD pallets and containers along the length of track and to interface with motor powered conveyor equipment and single level storage deck system (ETV: multi-level storage deck system) with friction powered roller decks.

The vehicle is an independent free standing unit with a motor powered roller deck to transfer ULD’s between interfacing equipment systems and is equipped with friction drive extractors on both sides of the deck. An operator platform is fitted to the TV for semi-automatic or manual control by an operator.

Steel Structure Assembly

The TV’s steel structure consists of a heavy duty welded construction to which four wheel assemblies, the operator platform and the roller deck are bolted.

Horizontal Drive Unit Arrangement

Two of the four wheel assemblies are driven by geared electric motors with brakes and are controlled by means of frequency inverters.

Automatic slow down and stop systems are at each end of the track to prevent vehicle overrun. These are initiated by the vehicle’s position detection system and limit switches.

In case of failure, hydraulic buffers with end of aisle rigid buffers are installed.

Rails / power rails / position detection

The vehicle will run on and is guided by surface mounted double rails running the full length of the aisle. Rails are laid horizontal and parallel with each other, are anchor bolted to the floor, shimmed and/or grouted to distribute point loads.

Operator Platform

An operator platform is located at one end of the vehicle, equipped with operator controls for power on/off, longitudinal drive, docking, load unit transfer and emergency stop.

Extractors

Extractors / friction drive assemblies are fitted to either end of the roller deck to drive friction powered storage decks placed next to the TV aisle.

Manual

The vehicle is manually controllable by an operator on the platform. The operator touch panel is used to control the vehicle movement and the roller deck.

Semi-Automatic

The operator touch panel is available which permits the operator on the platform to input the required deck location and when initiated, the vehicle and its platform automatically travels to and docks precisely at the required deck position.

Automatic

Automatic remote control is available where the required deck location is downloaded from the MHS / WMS IT-system to the vehicle’s PLC control. When initiated, the vehicle and its platform automatically travels to and docks precisely at the required deck position. Automatic loading or unloading of the ULD is then effected.

Safety Systems

Safety sensors and equipment interlocks are also installed on the vehicle to prevent unsafe actions arising from and including;

Emergency stop “mushroom headed” press buttons are located at principal maintenance points and at the operators control console.

If you need more information or have any questions, please do not hesitate to contact us at info@saco.aero

- Operating height: 508 mm